Sukut Construction LLC is one of the largest heavy civil engineering contractors in the western region. Headquartered in Santa Ana, CA, they bring in over 50 years of superior performance on a wide variety of residential, public, commercial, and industrial projects.

The company has extensive experience successfully working on large and challenging projects, with dams being one of their competencies. They’re currently working at Trampas Canyon Dam and Reservoir project in Southern California.

This project entails moving over 3.7 million cubic yards of material to buttress and raise an existing earthen dam 40 feet; importing over 600,000 tons of granular filter blanket materials; construction of inlet and outlet structures; a 600-feet-long concrete spillway; 700 feet of 63-inch micro tunneling; three MSE wall, instrumentation, reservoir aeration systems; 5,500 feet of 30-inch CML&C distribution pipe; 6,800 feet of asphalt access roads; and a dam control building.

With a large project like this, Sukut’s personnel have little time to spare. When it comes to getting accurate topos, they used to have to relegate overtime hours to do the physical work required to capture site data—sometimes even coming in on a Saturday to complete it.

GPS Program Manager Matt Eklund knew he had to find a solution to get the data his team needed in less time. He chose Propeller and it’s PPK solution to survey the site via drone.

Propeller PPK gives Sukut accuracy down to 1/10ft site-wide

With Propeller PPK, Sukut saves time and money getting topos for the Trampas Dam project. Propeller PPK is a unique workflow that uses DJI’s Phantom 4 RTK drone and one AeroPoint as a passive base station to collect drone survey data accurate down to 1/10ft site-wide.

“The idea that you can eliminate all that time and cost and get an accurate topo? That’s huge,” said Eklund.

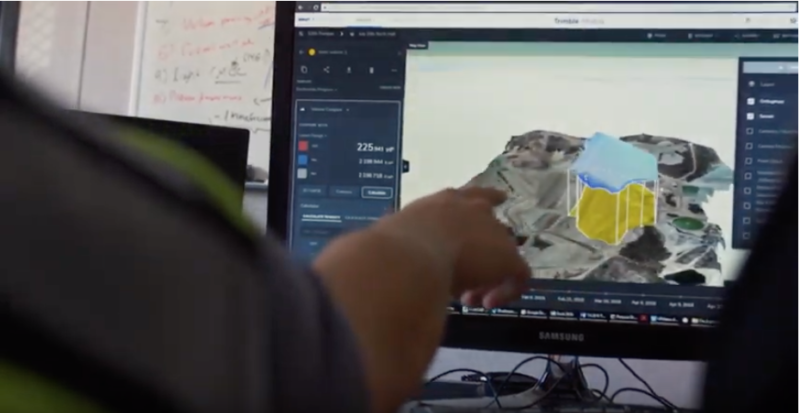

But this just covers the data collection side of things. Coupled with Propeller’s data analytics and visualization platform, Sukut gets 3D site surveys with all the measurement and analysis tools needed to report out on quantities, volumes, and more. “It gives you the visual tools to make informed decisions,” Eklund said.

“The first couple datasets I got back that I tried were more accurate and more consistent than anything I was producing,” noted Eklund. “That’s when I was onboard.”

And for Eklund’s team, the Propeller user interface is similar to tools they’ve seen before, so it takes little time for his team to get the hang of it. They can get the information they need easily, without much prior training.

Aerial surveys had a weeks-long turnaround for a site moving 20,000 yards a day

Before working with Propeller, Sukut used aerial surveys to get quantities for their site due to its large size. But that method was costly and had too slow a turnaround for the fast-moving project.

“Not only does an aerial cost upwards of $20,000, it’s a minimum of three weeks to a month before you get a contour map back,” said Eklund. “With photogrammetry and Propeller, you get a colorized point cloud, and you get a rich dataset that is not only useful to our project managers and project engineers, but also provides a visual record of the site.”

This level of detail and a fast processing turnaround is vital for a fast-moving site like Trampas. When Sukut is moving 20,000 cubes per day (that’s equal to more than six Olympic-size swimming pools), working on data that’s weeks old can mean missing big changes and potentially losing money.

“If something’s going wrong, you don’t want to know a month later. You want to know the next day, if possible,” said Eklund. “It allows red flags to go up earlier and you can make changes earlier. So, with respect to that, it’s saving money.

Exporting and visualizing data used to be hard

“Before Propeller, I was importing my CAD work to Google Earth. The problem with Google Earth is that it updates maybe once a year. I cannot see the excavation, I cannot see the progress as we go on in the project,” said Project Engineer Marlon Delgadillo.

“With Propeller, you just fly and all of a sudden I have real data. I can see what’s going on with my project as the months pass by.”

Propeller takes care of the photogrammetric data processing on our servers. There’s no desktop software to install. No computers are tied up processing datasets. And because drone survey only takes a couple of hours, even for large sites, they can get up-to-date visuals as often as they want to fly.

“At the end of the day, I can upload a dataset and I know that when I’m going home, someone on the other side of the earth is waking up and processing my software while I’m sleeping. More times than not, in the morning, it’s available,” said Eklund.

And because the visualization platform is cloud-based, Eklund and his team can access their 3D site surveys from anywhere.

“Having that 3D, point cloud, Google Earth-style experience where anybody from anywhere in the world, essentially, can be a part of that site without having to travel has become a point in our meetings,” said Eklund. “Not only are we looking at spreadsheets and PDF plans, we’re also bringing up the Propeller site.”

“The datasets speak for themselves.”

When it comes to that final 3D site survey, having an accurate, real-world model to use and share is invaluable for project managers and personnel alike. And to get that kind of data, they need a simple, reliable drone surveying workflow.

After putting those two things together, “I think the datasets speak for themselves. It’s nothing that you have to bring anyone onboard with. It’s data that’s intrinsically and obviously valuable,” Eklund said. “There’s not any pitch. The pitch is ‘here’s the link to the website.’ Done.”