Home/How Svevia improved collaboration, planning, and long-distance teamwork in quarries across Sweden

How Svevia improved collaboration, planning, and long-distance teamwork in quarries across Sweden

Svevia is using Trimble Stratus, Powered by Propeller. Trimble, the global leader in positioning technologies, was an early partner of Propeller. Our teams work closely together to deliver Trimble Stratus survey-grade drone data solutions for the heavy civil industries.

Swedish-based contractor Svevia specializes in building and maintaining roads, bridges, ports, and other infrastructure. As the leading operating contractor and one of the largest road and construction companies in Sweden, Svevia has used drone survey technology for years—but only since adopting Trimble Stratus, powered by Propeller, has that program really taken off. (Pun intended—we couldn’t resist.)

When Philip Andsen joined Svevia’s small team of measurement engineers three years ago, their workflow was time-consuming, highly technical, and expensive from start to finish.

Read on to learn how Svevia has since transformed their survey workflow to enable more frequent, accurate flights; optimize drill planning; and improve long-distance collaboration across an entire country of quarries.

The challenge: time-consuming and expensive surveys with limited integration across quarries

Philip and his fellow measurement engineers needed a faster way to collect data. The quarries Svevia surveys are about 20 hectares on average, and the time and expense involved with the team’s old survey methods made the survey process too laborious to survey as often as they would have liked.

The sheer time cost became a particular problem in spring and autumn, when the weather and daylight hours combine to create a tiny window of flight time. “We needed a faster, more user-friendly way to collect data,” said Philip. “We also wanted to be able to fly more often without losing time, especially in autumn when it gets dark early in the north of Sweden.”

Svevia’s highly technical workflow also required knowledge of photogrammetry, which meant lots of travel time (and associated costs) involved with getting the three measurement engineers to the quarries in need of a survey. Even as drone technology grew more economical, the team relied on complex GNSS receivers and other expensive equipment to complete their survey workflow.

The solution: a user-friendly workflow to improve long-distance collaboration and make accurate planning a reality

Philip describes the process of watching Svevia’s survey workflow transform as “eye-opening.” “It was like, why haven’t I used this before?” he said with a laugh. Although he and the team had worked with drones before, they started using AeroPoints instead of traditional ground control, dramatically reducing their time in the field and making quick quarry surveys a simple task. “Our quarries are about 20 hectares on average,” Philip said, “and one quarry is now under 30 minutes’ flight time.”

Even more exciting to Philip than spending less time in the field was the time savings of outsourcing their survey data processing. “Propeller’s outsourced processing gets us data back much faster, and the accuracy is great. We can trust the data that is coming back,” Philip said. Svevia’s measurement engineers are now free to focus on the data itself, as the team can survey three or four quarries per day (instead of just one) and get the data back the next day.

“The whole process is so easy, I could almost have my kid do it,” said Philip. “Initially, we wanted a smarter and faster way to complete stockpile inventory—but Propeller delivered so much more. Now, one picture says more than a thousand words.”

Collaboration in the cloud

Propeller was Svevia’s first foray into cloud-based survey software, and it’s paid off in ways they didn’t expect. With a cloud-based portal that everyone can use, the data that comes from quarry surveys isn’t just accessible to one individual with technical training. Instead, it’s available to everyone instantly without the need to manually share it. “Before, we measured our stockpiles, and that’s it. But now, we get so much data that everyone can use rather than just one person,” Philip told us.

“The best thing about Propeller is that it’s online, so you can share information easily. Comparing data from a quarry manager with the data in Propeller acts like a control, clearing any question marks easily and quickly. It also makes sharing data with the quarry manager very easy.”

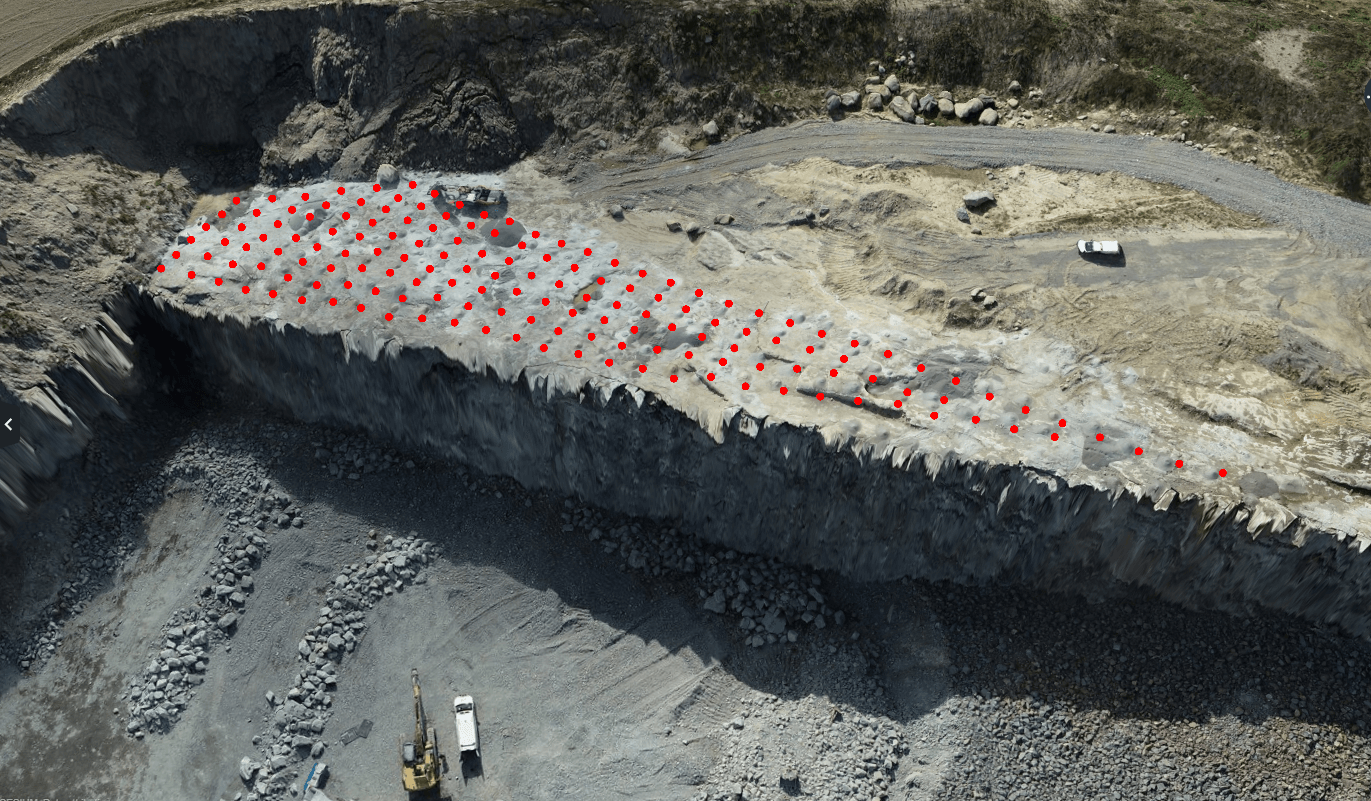

Communication between the drone pilots and 70+ quarry managers, working leaders, and other quarry staff has dramatically improved now that everyone has access to the same platform. For example, if a driller encounters a problem with drill holes, they call Philip, who can check Propeller and adjust the plan with just a few clicks. Both team members are looking at the same picture in real time, even if they’re collaborating from opposite ends of the country.

And because it’s so easy to log in and make a measurement, the drone pilots can check each other’s work within minutes. “I can now make planning files for quarries I’ve never been to,” said Philip. “I know what’s going on in quarries all over Sweden without having to travel there. Propeller makes our long-distance work possible.”

Accurate and optimized planning

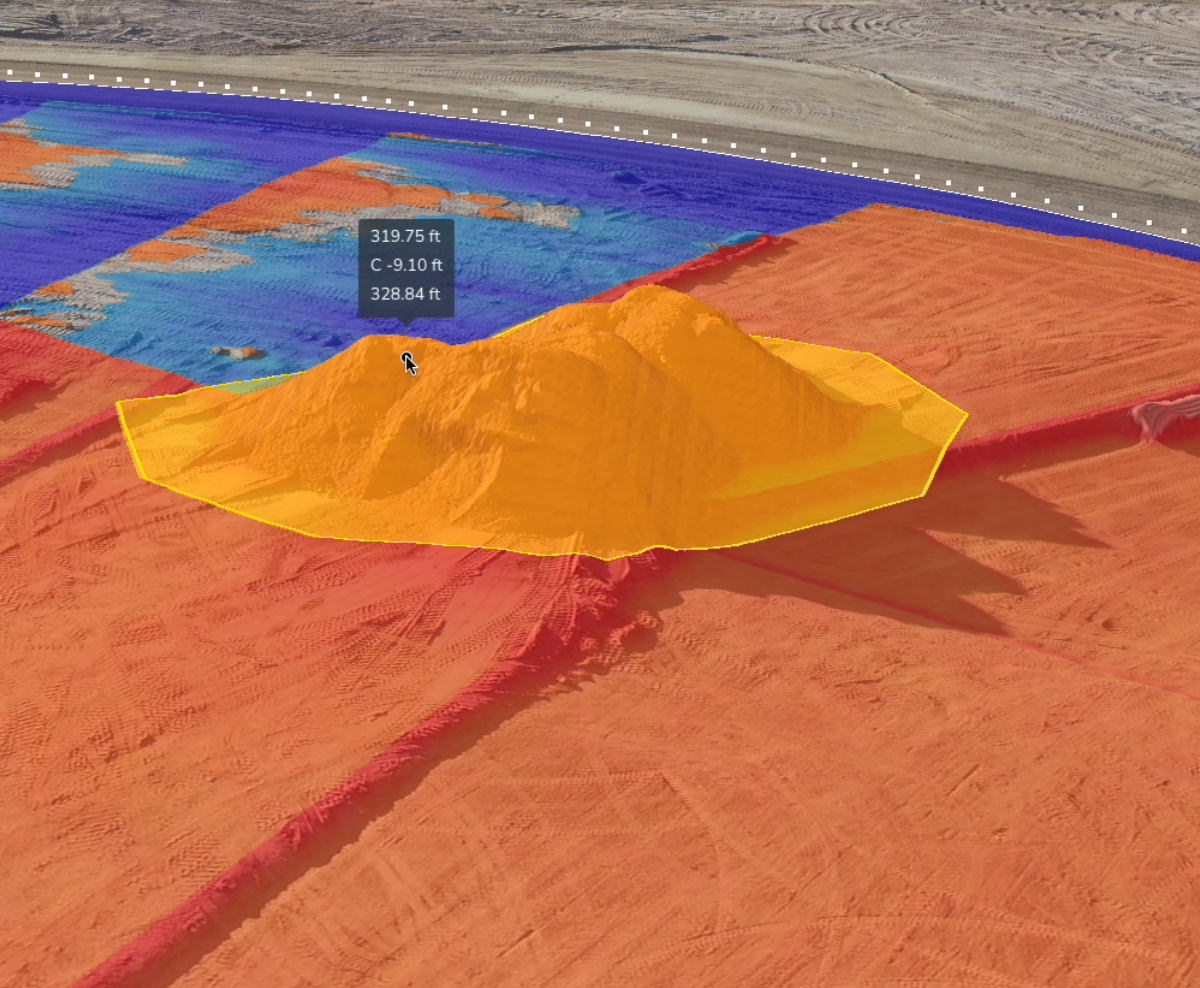

Svevia’s measurement engineers now use Propeller at every stage of planning, from measuring how much volume they’ll need to build ramps to creating drill plans, visually plotting the position of every blast, and calculating a quarry’s outtake over time. The 3D map enables them to determine how much drilling should be done and where, so they know when they can move to the next quarry.

Svevia’s plans can be extremely detailed, including how many meters they need to drill and how long the process will take. This has proven a very effective strategy for both production output and customer satisfaction, as the team can effectively plan how long they will need before delivering an order.

Svevia is even using Propeller to predict vibration points and plan blasts accordingly to keep nearby buildings safe. “Propeller helps us identify vibration points, how close they are to the blast, and in what direction, so we can adjust the blasting plan before drilling to stay under the vibration threshold,” said Philip.

Want to know how Propeller can help you?

Learn more about Propeller’s products, pricing, and how to get started on your site.