Home/How Lhoist uses DirtMate to boost operational efficiency by 22%

How Lhoist uses DirtMate to boost operational efficiency by 22%

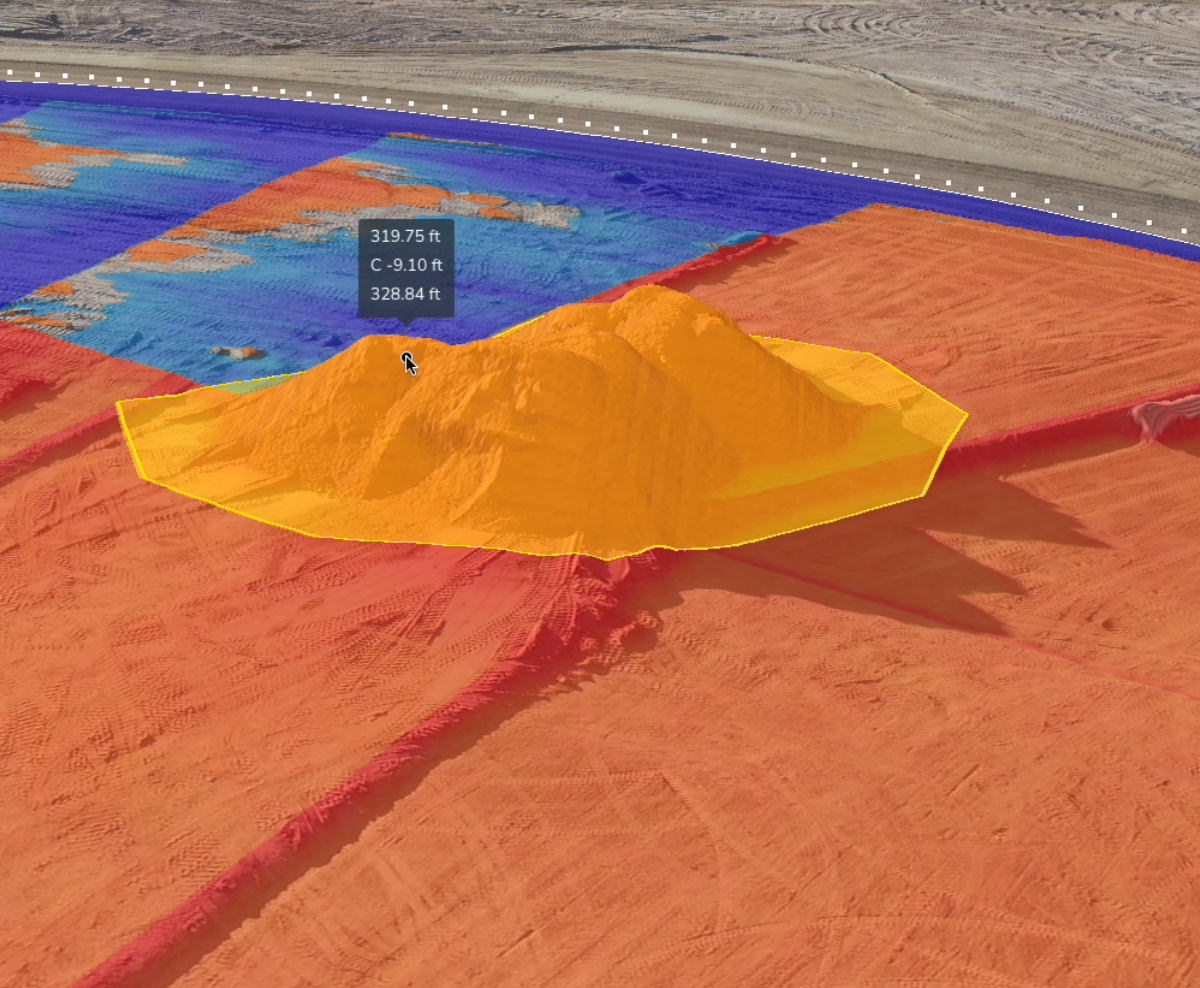

Lhoist, a 136-year-old family-owned company, supplies high-quality minerals to global industries including steel, civil construction, water treatment, glass manufacture, building materials, and air pollution control reagents. After a decade at their Amargosa Valley quarry in Nevada, changing geology and shifting mining ratios made efficient operations increasingly difficult. Martin Dillon, P.E., Lhoist’s Senior Business and Operations Manager, was tasked with finding a way to track productivity, reduce idle time, and increase efficiency. That’s when he found DirtMate. Changes in the mineral deposit structure made mining operations at Amargosa increasingly complex. On paper, they had the necessary resources to move the material efficiently—but in reality, they were barely getting by. Martin’s shortlist of challenges included: Before DirtMate, we had a basic spreadsheet where we took load counts and assumed a fixed volume. We could never get these values to reconcile and didn’t have our true cost structure as developed as we do for other areas of our operation. In retrospect, it was a very haphazard way to run the mine compared to how we operate today.” —Martin Dillon, Senior Business & Operations Manager Martin learned about DirtMate by chance after sitting next to another Propeller customer on a flight. After a bit of research, making the business case to Lhoist’s leadership was an easy feat. They quickly deployed DirtMate across their scrapers and dozer. Now the team doesn’t just have the data they need to adapt as a site’s geology changes—they’re operating more efficiently than ever. Real-time machine utilization lets them track every load, haul cycle, and idle minute so they can train quarry leadership and equipment operators to work smarter. DirtMate’s universal compatibility has given Lhoist the OEM-agnostic solution they needed across their mixed fleet of equipment, some of which can’t be retrofitted with newer systems. We saw ROI on our productivity in less than a month. It was approximately four weeks on idle fuel savings alone.” —Martin Dillon, Senior Business & Operations Manager With DirtMate, we can actually schedule and have a high degree of certainty regarding how much we’ve extracted and how much volume is left to go from our imported isopatch models.” —Martin Dillon, Senior Business & Operations Manager Since adopting DirtMate, Lhoist has gained unprecedented visibility into their quarry operations, helping them make significant changes. Cutting idle time has effectively increased operational time by 22%, and fuel savings alone paid for their annual DirtMate subscription in less than four weeks. With a lighter offsite engineering workload, improved maintenance costs, and more efficient extraction, DirtMate has completely changed the way their Amargosa Valley quarry operates. Another site challenge was mysterious ore grade degradation in their stockpiles. Propeller, powered by Dirtmate and drone data, helped Martin pinpoint the issue: operators were accidentally digging into bedding material, contaminating the clay. By closely and confidently tracking material movement, Lhoist reduced stockpile conversion loss from 15% to under 3%, preserving valuable graded ore. Before DirtMate, this was absolutely maddening to the site and management teams. Ore was downgrading for no apparent reason. Getting back that 10-12%+ of ore that’s not being wasted is huge.’” —Martin Dillon, Senior Business & Operations Manager Learn more about Propeller’s products, pricing, and how to get started on your site.

The problem: Untracked idle time and production bottlenecks

The solution: Real-time productivity data

Lhoist’s favorite features and workflows

The results: 22% more operational time in the same number of labor hours

Want to know how Propeller can help you?