Home/How the LPX Group uses drone data to keep their large team connected

How the LPX Group uses drone data to keep their large team connected

Louisville Paving and Construction (LPC) uses Trimble® Stratus Software, Powered by Propeller. Trimble, the global leader in positioning technologies, works closely with Propeller to deliver drone survey data solutions for the construction industry using Trimble Stratus.

LPC purchased Trimble Stratus and their other technology solutions through SITECH MidSouth, a Trimble authorized dealer.

As the largest civil contractor in Kentuckiana, the LPX Group and their family of brands, which includes Louisville Paving and Construction, have their hands full. They run ~300 projects a year with a team of 400 employees, doing everything from heavy highway work to site development, utilities, and asphalt production.

Construction Technology Specialist Jack Hayes and the team at LPC get most of their tech from SITECH MidSouth, an authorized Trimble dealer. When SITECH’s Adam Coomes and Scott Thomas demoed Trimble Stratus powered by Propeller, Jack knew they’d found their ideal surveying solution. “It turned out to be everything we needed and more,” he said.

Read on to learn how Jack made an easy business case for drone surveying, scaling from one drone to two in less than a year and adding new hires to the survey team in the process.

The problem: Cumbersome, time-consuming surveys

When Jack joined LPC a little over a year ago, the team had used drone surveying before. But accuracy and processing were inconsistent, leading to some hesitation about fully embracing drone technology.

Without it, though, surveying posed some challenges:

- Time-consuming surveys: In road work, surveying multi-mile projects isn’t uncommon. This process often kept surveyors busy for days with a base and rover, focused on just one single project. Surveying stockpiles at the LPC asphalt plants also took longer than necessary. Kendall Roller, Project Engineer, observed, “Oftentimes, asphalt plant stockpiles were quantified by hiring an outside surveyor to fly a drone. The survey processing took multiple days, and there usually wasn’t a good inventory management system for the data.”

- Lean survey team: When Jack joined the team, there were just two surveyors handling hundreds of projects per year, presenting challenges when they were tied up on projects. They needed a way to be off-site within hours, not days.

- Expanding operations: LPC has traditionally completed work close to Louisville, but recently has expanded into new markets, making it challenging for the survey team to cover all projects.

- Multiple trips: As if visiting sites further afield weren’t hard enough, initial surveys tended to miss things, necessitating trips back out to far-flung worksites.

“They had me do a progress topo by hand in my first week there,” Jack told us. “It was a huge, hilly site, and I was climbing stockpiles on all fours. I told them, ‘Please get me a drone.’ I knew it could be done easier.”

The solution: Freeing up time with fast and efficient 3D mapping

SITECH MidSouth had a solution: DJI’s Mavic 3 Enterprise, a longtime customer favorite amongst Propeller’s PPK-compatible drones. Jack is a big fan of the Mavic 3E’s camera, which is equally capable of site surveys and marketing videos—due in part to its long battery life. He also loves the mission planning feature, which they can use in the field to program an automated flight.

Since 2006, DJI has led the world with civilian drone innovations and creative camera technologies, transforming industries from construction and agriculture to conservation and public safety.

Trimble Stratus was new to the survey team in August 2023, but they picked it up quickly. “We fly 30-50 times per month, and that was pretty much as soon as we got the drone,” said Jack.

The team was so busy that they bought a second Mavic 3E within a few months, hiring another pilot to help them cover demand. Today, both the construction and asphalt sides of the business use Trimble Stratus to track progress and get stockpile quantities.

Trimble Stratus has been a great tool for our Project Managers to track production and to accurately forecast completion dates. You can fly a site and have the data back in a format you can use in a few hours. It also adds another level of professionalism in communications with our clients, allowing us to create progress exhibits and real time photos of current conditions. It’s been an absolute game changer. Everyone from our foremen to our directors uses Trimble Stratus. — Bryan Heath, Survey Operations Manager

LPC’s favorite features and workflows:

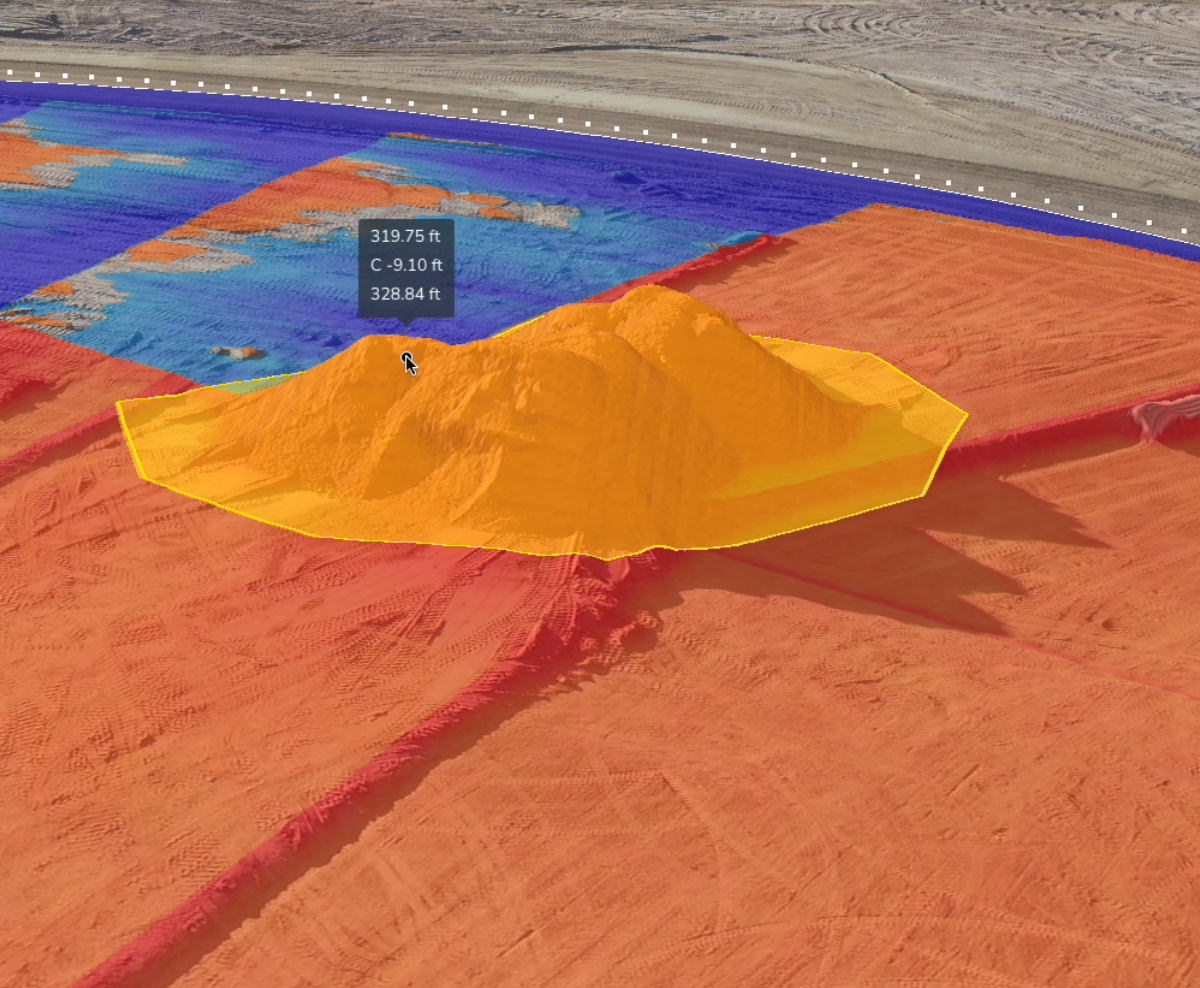

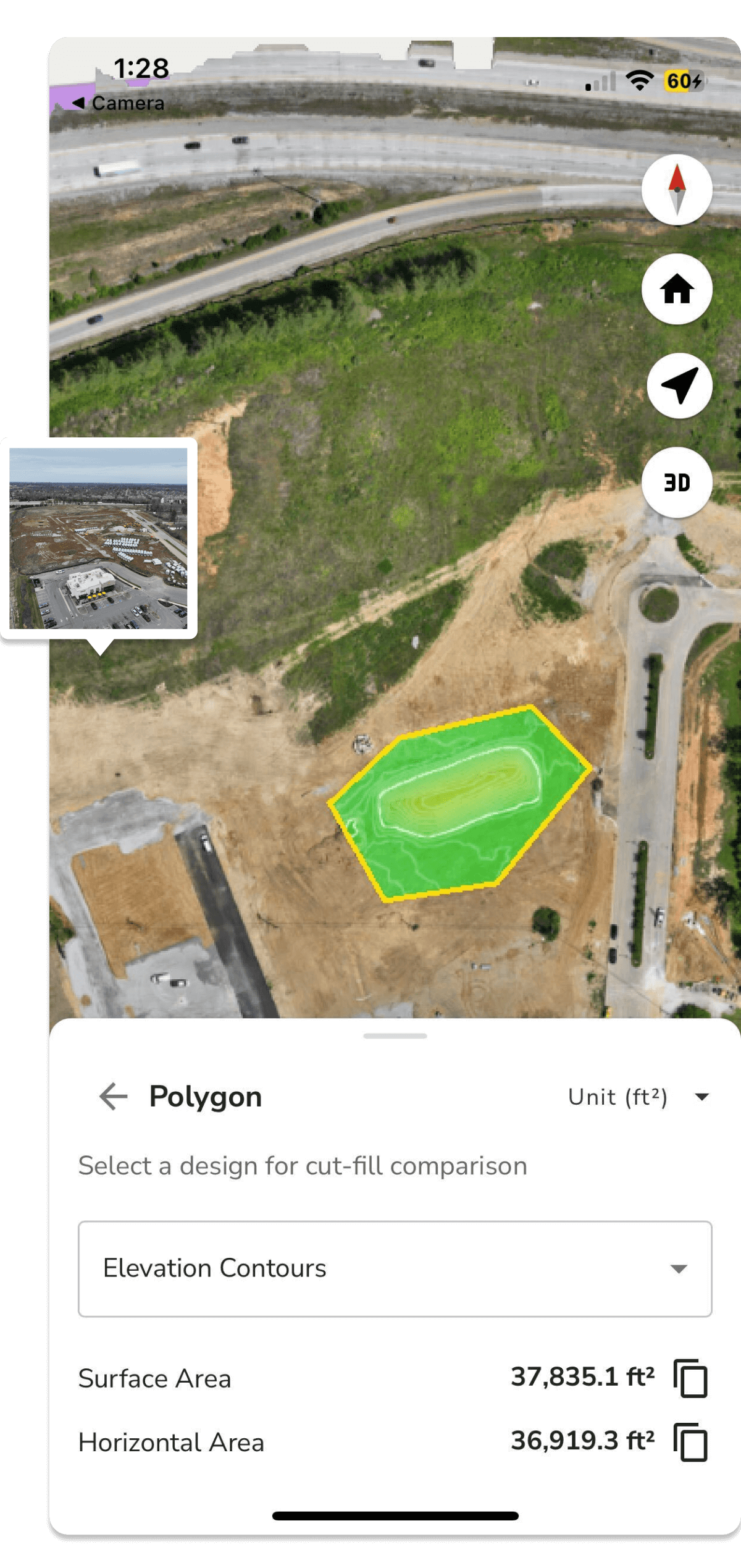

- Getting cut-fills anywhere: Project managers use Trimble Stratus to get cut-fills and price change orders. But this level of insight isn’t tied to a desk; the team also uses the mobile app to get cut-fill quantities right from the field.

- Stockpile quantity checks: Gone are the days of scrambling up a big stockpile on all fours. Now, the asphalt plant surveys stockpiles with a custom base volume to get accurate measurements from month to month. The new workflow has also eliminated the use of manual topos on the construction side.

- Creating better estimates: LPC’s estimating division uses Trimble Stratus to track production and check bid accuracy. They also study the data from drone surveys to improve future accuracy.

- Connecting field and office: The team can take still photos from the ground and upload them to the 3D site map, which has noticeably improved communication. “Honestly, the connection between the field and office that we’ve seen the most is the ability to take a picture and then georeference it on Stratus,” said Jack.

“Trimble Stratus isn’t just for big dirt jobs. We’re using it on all our small jobs too, especially with project documentation and model building. Most users say they can operate the platform with ease.”

—Jack Hayes, Construction Technology Specialist

The results

“Surveys that would have taken us two days now take two hours.”

—Jack Hayes, Construction Technology Specialist

- Doing more in less time: LPC’s expanding area of operations means they’re now getting jobs two or three hours away—a feat that Trimble Stratus makes possible. Not only are they surveying much faster, but they’re also making fewer trips back out to a site to catch things that were missed on an initial survey. “We’re getting a more accurate surface on the front end of things,” said Jack. Now that they aren’t processing the data, the team just has to upload it before moving on to other work.

- Reliable accuracy at scale: Survey accuracy is always top of mind for Jack and his team. “Accuracy makes or breaks a project, especially if we’re using a survey to build models,” he said. The accuracy of other systems didn’t meet their standards, so it’s no surprise that LPC had some initial reservations. “Whenever we would topo entrances that we have to tie into, my boss would have us do some [base and rover] shots on the road just to compare. It was under an inch every time. Management values accuracy highly, and Trimble Stratus impressed them. That says a lot.”

- Improved understanding: LPC relies heavily on models when starting a new project because they create a shared language that anyone can understand. As Jack noted, “When we build a model and load it as a design on Trimble Stratus, it helps identify problem areas and helps the Project Managers visualize the project surface.”

“When clients are aware that the project is being surveyed with a drone, it gives them an added level of comfort that the project is being built as designed and that LPC is monitoring the quality of the project from all angles.” —Dustin Gerkins, Project Manager

Want to know how Propeller can help you?

Learn more about Propeller’s products, pricing, and how to get started on your site.