Home/How STORY Contracting ensures efficiency and accuracy through drone surveying

How STORY Contracting ensures efficiency and accuracy through drone surveying

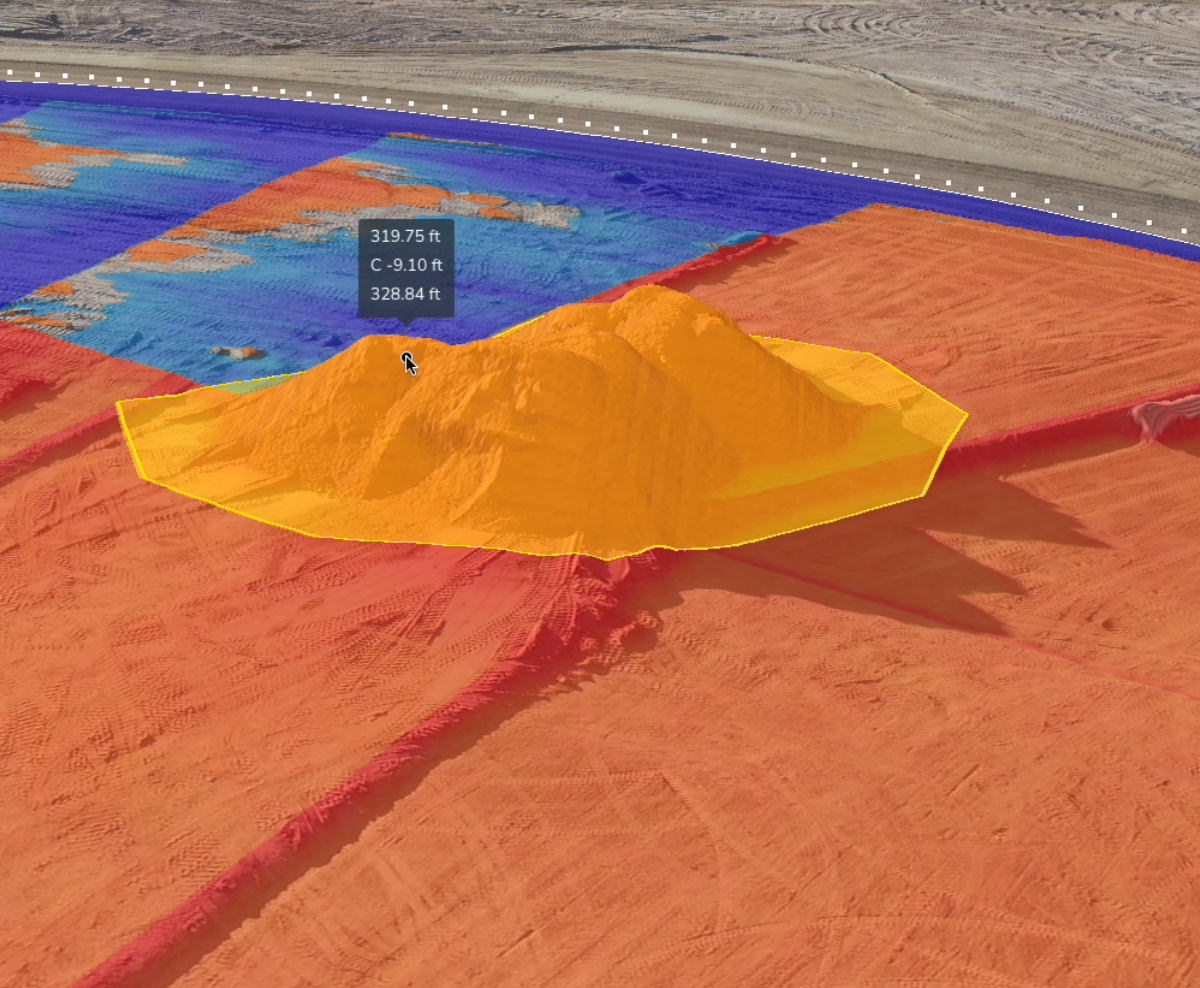

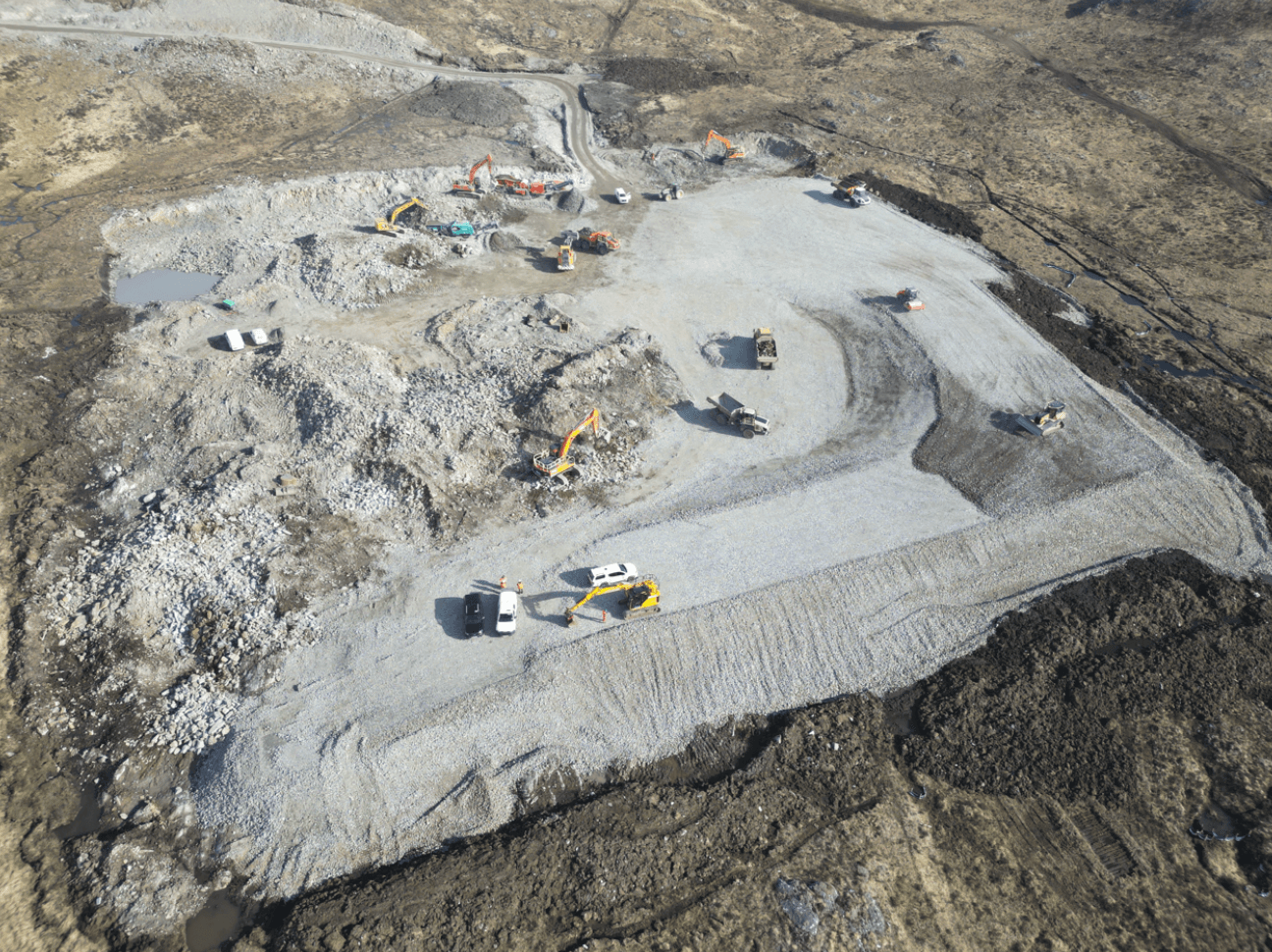

Story Contracting uses Trimble® Stratus Software, Powered by Propeller. Trimble, the global leader in positioning technologies, works closely with Propeller to deliver drone survey data solutions for the construction industry using Trimble Stratus. Founded in 1987, Story Contracting is a leading infrastructure and civil engineering company based in the UK. Known for its innovative use of technology and commitment to delivering projects on time, Story has built a reputation for excellence across rail, plant, and construction projects. By adopting Trimble Stratus, Story has been empowered with seamless data sharing and powerful 3D visualisations, transforming site operations, enhancing contract control cost and driving significant project savings. Key stats: 49 users Story Contracting were looking to improve how they accurately manage large complex infrastructure and civil engineering projects. Manual surveying methods and traditional data-sharing processes led to delays, data discrepancies, and inefficiencies, especially when validating contractor work and resolving disputes. Trimble Status platform facilitated accurate, up-to-date site data and seamless collaboration between field teams and office staff that was critical to keeping projects on schedule and within budget. “With our drone division receiving more and more requests for surveys, it was clear that we needed a platform which solved data storage issues, accurate processing but also one that allowed non-technical persons without high-powered laptops to view the outputs produced by drone processing software.“ – Gerald Brown, UAS Accountable Manager To address these challenges, Story adopted Trimble Stratus, powered by Propeller, to revolutionize their data workflows. The combination of survey-grade drone data, intuitive 3D mapping software, and Propeller’s PPK workflow streamlined the process of collecting, processing, and sharing site data. With AeroPoints providing precise ground control, Story ensured sub-20mm accuracy across projects, significantly enhancing confidence in their data. Regular drone flights allow teams to monitor progress and spot trends directly on 3D models, enabling faster decision-making and reducing disputes. This rapid, accurate feedback loop has empowered teams to address issues proactively, avoiding costly rework and delays. “The simple but very effective workflow for collecting data has freed up so much of our time. The AeroPoints have been a great addition to the family and in most cases we receive sub-20mm for our site control.” “The ability to view all measurements in 3D (mostly within 24 hours of capture) and then share directly with the project team or clients with a click of a button is impressive.” – Gerald Brown, UAS Accountable Manager “Regular flights allow the project teams to monitor and interrogate the data to spot any trends that are occurring on the site. The quality of data received on the platform is such that you are able to zoom in and then classify the construction site, allowing for detailed measurement reports that help validate scope of works and Bill of Quantities against what has been delivered on-site.” – Gerald Brown, UAS Accountable Manager By incorporating Trimble Stratus into their workflow, Story Contracting has not only transformed their site operations but also delivered measurable results. According to the team, “Had it not been for the software and technology on the project, our engineers would not have been able to record all operations in such detail and also have the ability to review the data post operations. This allowed the project and commercial team to compare data sets and validate volumes of stone placement and to reduce the value of subcontractor claims because we could substantiate what was happening on-site. Using Trimble Stratus opened many eyes to what the technology is capable of and what we can deliver.” The software allows project teams to analyze live data with final designs, the turnaround of this feature is very quick and helps highlight any short falls. Without this capability it would have led to slow traditional methods of engineers in the danger zone around large earth moving plant. One standout example came during a project where nearly 5,000 cubic meters of stone was found to be missing from the platform. “Once it was identified, it was quickly rectified with daily progress flights to track the increments. It was an eye-opener for everyone,” the team noted. Learn more about Propeller’s products, pricing, and how to get started on your site.

334 site measurements

175 surveys

The problem: Balancing time and accuracy for large-scale projects

The solution: Streamlining data workflows for fast, accurate analysis

– Gerald Brown, UAS Accountable Manager

Story Contracting’s favorite features and workflows

Trimble Stratus enables seamless data sharing, making it easier for teams to communicate and collaborate effectively. Project stakeholders can access and review survey data without any specialized hardware or software, streamlining how they distribute insights and coordinate across multiple sites.

Another feature that has been enhanced by the adoption of using Trimble Stratus is the ability to provide our Pre-construction team with accurate 3D data for use in adoption of early development to mitigate option selection and protracted stakeholder engagement. The team are now able to analyze, create measurements, cross sections and various other volume calculations in-house. This collectively means projects can be turned around much quicker and more efficiently.

Propeller’s PPK workflow, combined with AeroPoints, ensures that drone data is consistently accurate and easy to process. These smart ground control points deliver survey-grade precision, minimizing errors and reducing the need for manual rework. This upgraded workflow has been instrumental in delivering fast, reliable results across Story’s projects.

With precise 3D models and efficient workflows, Story Contracting is better equipped to quickly validate contractor applications and resolve disputes. By comparing actual site conditions with submitted claims, teams can ensure accuracy, saving time and preventing costly misunderstandings or overpayments.

The result: Fewer project delays and lower costs

Want to know how Propeller can help you?