Home/How Civiltech avoids rework by catching easy-to-miss details

How Civiltech avoids rework by catching easy-to-miss details

Civiltech Solutions uses Trimble Stratus, powered by Propeller. Trimble, the global leader in positioning technologies, was an early partner of Propeller. With SITECH Construction Systems, we work to deliver Trimble Stratus’s survey-grade drone data capabilities to contractors of all sizes in the heavy civil industries.

Civiltech Solutions is a leading civil engineering firm headquartered in Darwin, the capital of Australia’s Northern Territory. Civiltech specialises in delivering state-of-the-art engineering and project delivery services and has carved a niche for itself by offering bespoke GIS and surveying solutions at the forefront of the civil infrastructure industry.

Director Leigh Carnall has been a member of the Civiltech team for well over a decade. He’s worn many hats over the years, but these days, he works as a design certifier to coordinate, schedule, calculate, and verify the particulars of Civiltech’s projects. Before he found Trimble Stratus, Leigh grappled with the limitations of GPS and machine guidance, lacking sufficiently accurate data for critical tasks like determining pavement depths and material placement. Checking work required surveying equipment that was both cost-prohibitive and limited in scope.

Read on to learn how the transition to drone surveying with Trimble Stratus has marked a significant turning point in Civiltech’s approach to project management, data analysis, and bidding.

The challenge: Outdated survey techniques and inaccurate machine control

Before Trimble Stratus entered the scene, Leigh found himself at a troubling midpoint between the old, manual ways of working—like verifying constructed earthworks with survey pegs, string line and batter boards—and the advent of modern RTK-GPS machine guidance/control technology that the Contractor was using. He often struggled to verify contractor data without his own RTK base and rover set-up, which was typically cost-prohibitive for ad-hoc usage for earthworks checks.

Even if he could manage to secure a traditional survey, he kept bumping up against a problem: spot checks are just that. A RTK rover measures a point in isolation. Leigh wanted to check millions of earthworks points across Civiltech’s worksites.

Against this backdrop, Civiltech faced a significant challenge: how to modernise their surveying workflows while maintaining a high standard of accuracy. “Data has to be both accurate and reproducible every time for the information to be valid,” Leigh told us.

The inability to effectively visualise and measure critical site features made accurate, efficient project delivery difficult. “We wanted to document the whole site with centimetre-level accuracy, including imagery. That desire is what led us to Trimble Stratus,” Leigh said.

Arnhem Highway - Adelaide River floodplain upgrade project

The solution: High-accuracy drone surveying with Trimble Stratus PPK

Leigh first put Trimble Stratus to work on the Arnhem Highway upgrade project. “Being able to fly the whole site and capture all of the information we needed was fantastic,” he said. “It used to take us six hours to capture ten settlement monitoring points across our worksite. With Trimble Stratus, we’re collecting millions and millions of points across the 6 kilometres of embankment in a matter of hours.”

Accuracy is of critical importance to Leigh, who needs assurance that any data he approves is precise. “Trimble Stratus has proven invaluable because I’m signing off on the contractor’s data. I can fly the drone to verify, which provides surety to what I’m signing off on.”

It wasn’t long before Leigh saw Trimble Stratus as far more than drone surveying; he now discusses it with clients as a comprehensive solution. Not only can the team gather millions of data points, but they can also share intricate 3D site maps and aerial imagery with clients, enhancing collaboration, worksite planning, jobsite safety, jobsite compliance recording and overall project progress.

Efficient data sharing

Point clouds and raw data are tricky to use, so Leigh used field requests to grab data for clients whenever they had a question about a measurement. He might also send point cloud screenshots alongside the data to help provide a visual. The whole process was manual and time-consuming.

With Trimble Stratus, Civiltech can easily share survey data with clients using interactive 3D models. Instead of pulling data and sending screenshots, they can grant their clients direct access to the 3D site maps in Trimble Stratus. This new level of access has transformed their clients’ engagement, empowering them to measure and interact with their project data directly.

“We can have someone jump in, and within 10-15 minutes, they’re measuring stockpile volumes and cross-sections. If you can use Google Earth, you can use Trimble Stratus.”

Internal engineers and other technical workers have also picked up the new workflow with ease. Leigh noted, “You walk around with engineers and show them the phone, and they’re blown away by the amount of information you can use right there in the field.”

Enhanced monitoring and analysis

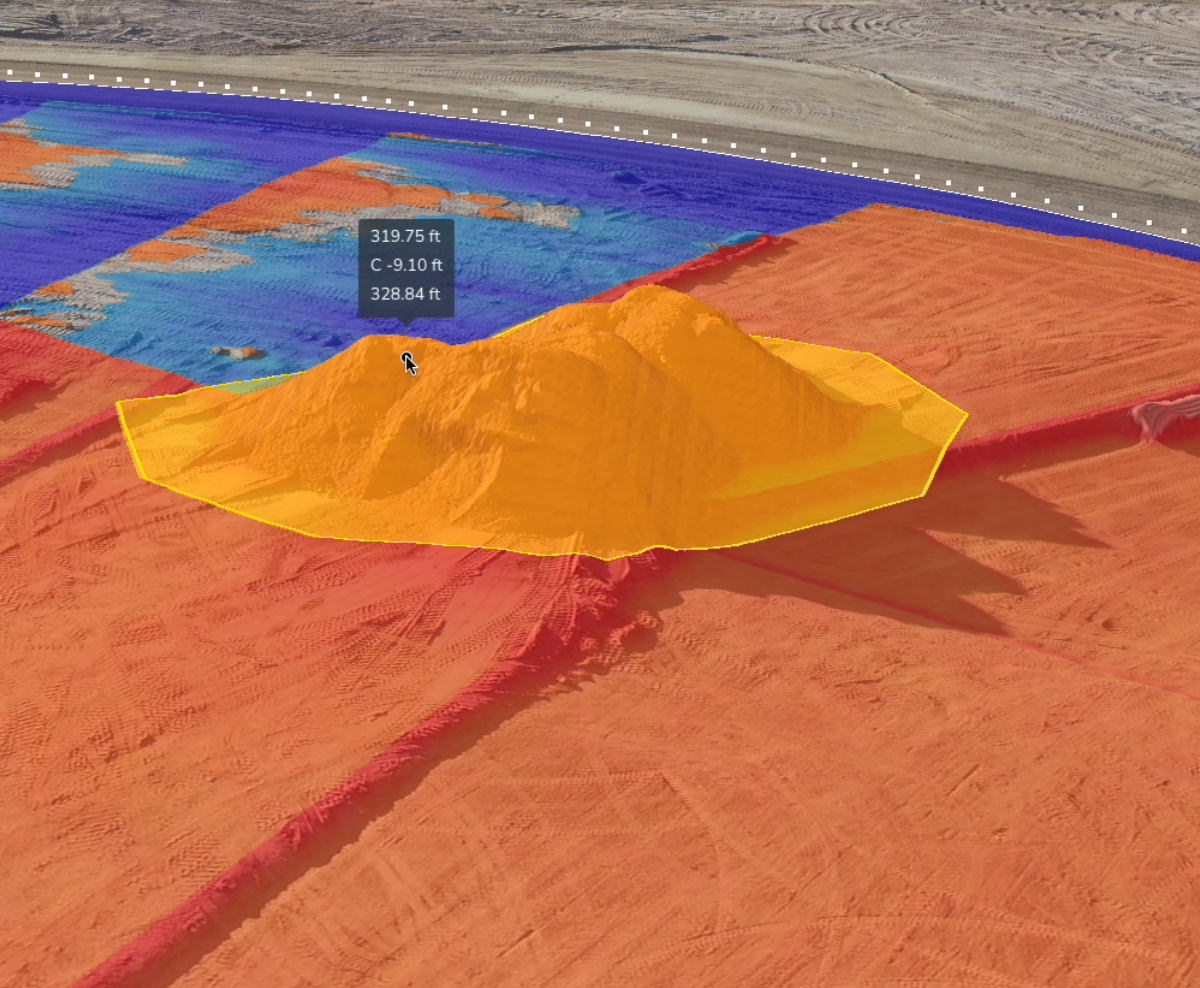

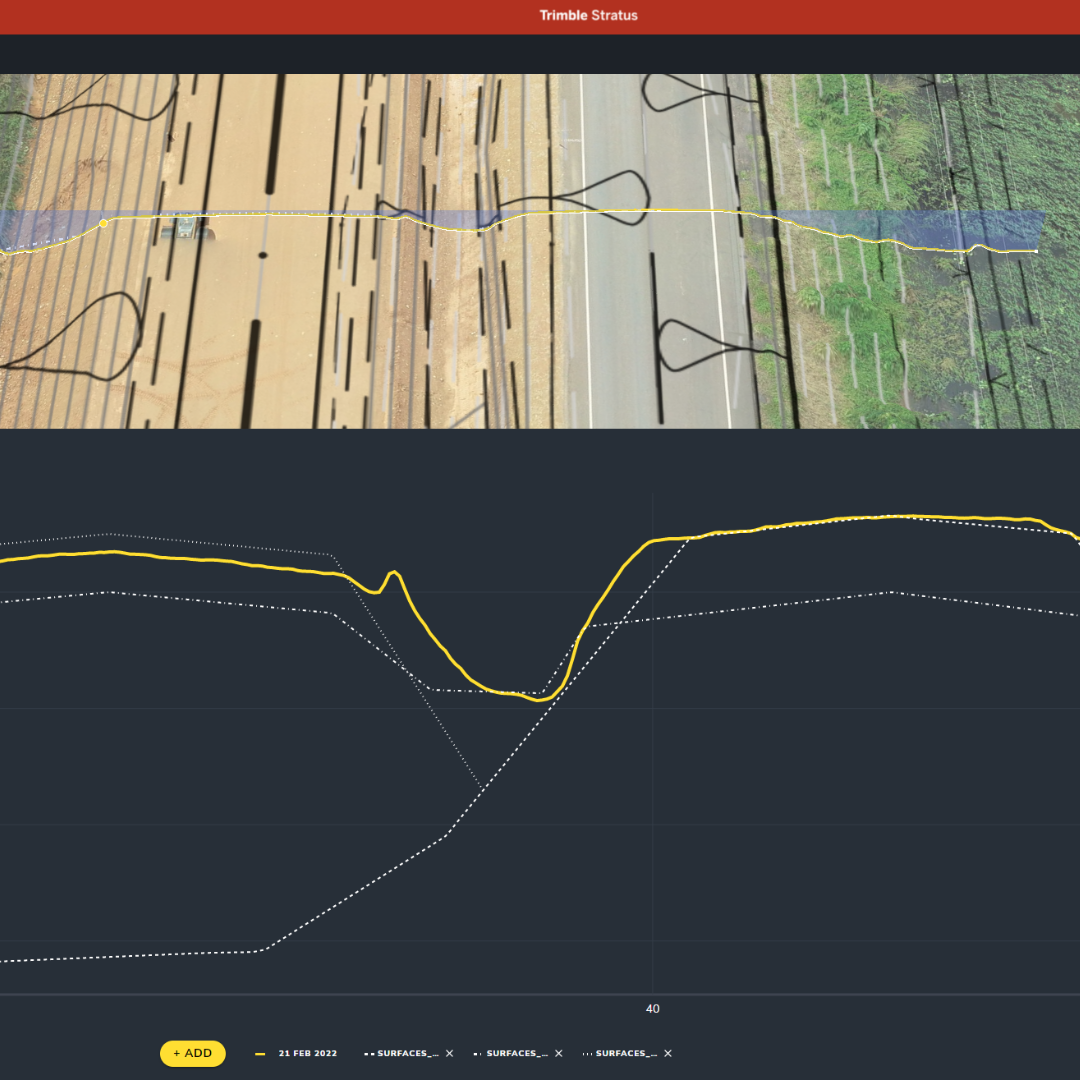

One of the best use cases Civiltech has found for Trimble Stratus is to monitor the settlement rate of surcharged embankments. The team often has to ‘surcharge’ embankments in floodplains by adding additional weight to the soil and letting it settle over a period of several months.

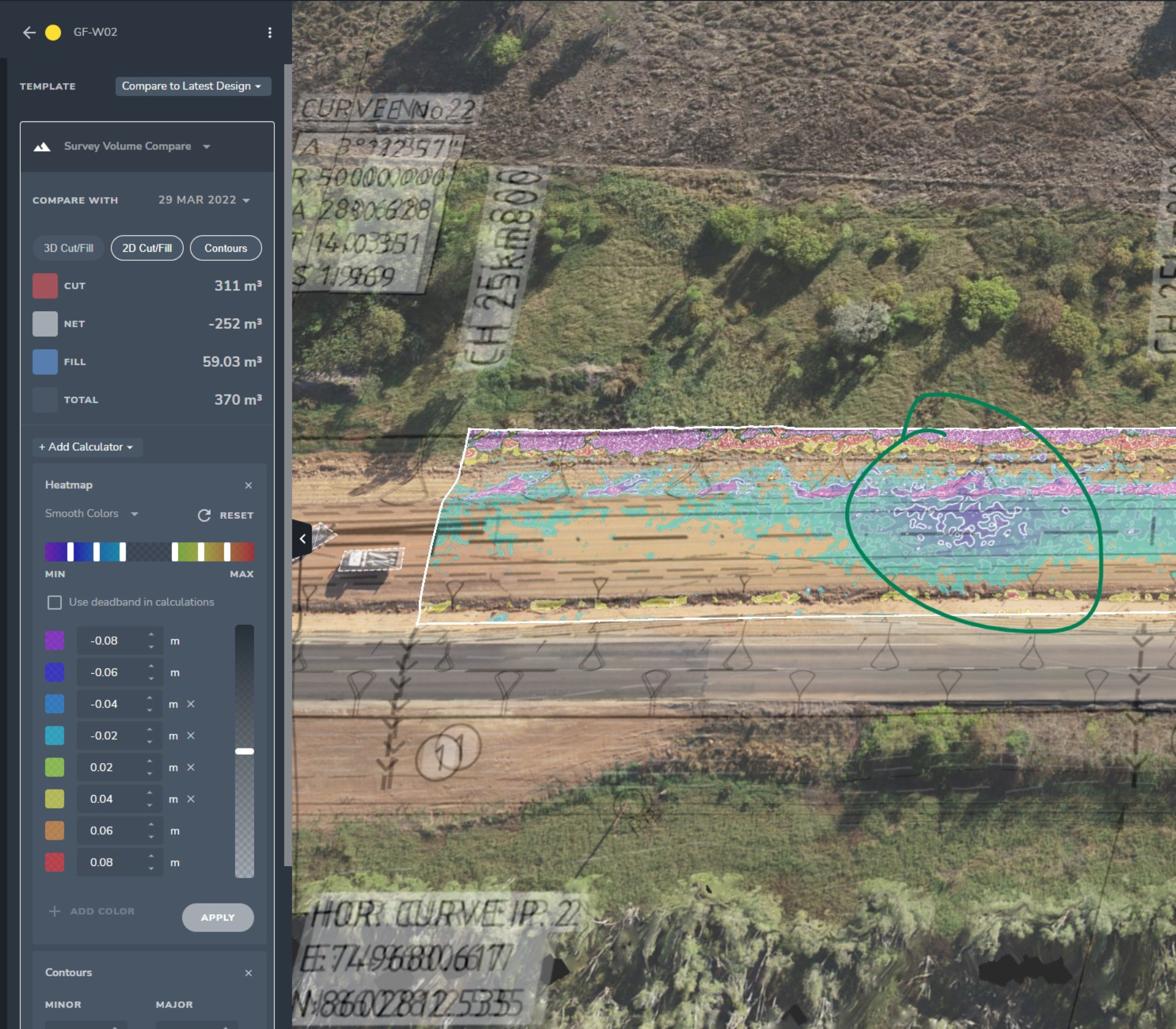

The traditional way to monitor soil compression was by using settlement rods placed every 300 metres. Levels were measured each month and recorded in an Excel spreadsheet for comparison to the month before. The problem with this method is that it leaves a lot of room for missing something; with one point every 300 metres, there might easily be locations between these points that are settling more, therefore additional material or engineering assessment is required. From this first pass drone derived surface we could go and understand this location further.

Trimble Stratus enabled comprehensive monitoring, identifying variances that likely would have been missed otherwise. By flying a drone, Leigh says, you can start to identify areas that are statistically different from the others. An area that has settled more will show up in Trimble Stratus when you compare the surveyed surface to the design file or even previous surveys.

“We’re running volumes and cross-sections to look at how much work is done and how much is left to go. Trimble Stratus is a very valuable tool for the client, Contractor and Designer in understanding what’s left to do on site.”

Precise bidding

Trimble Stratus also helps Leigh identify discrepancies in existing project features, allowing for more accurate bids—a level of detail that simply wasn’t attainable with their older workflows. With greater insight and increased spatial awareness at the pre-bid stage, the team can identify existing features that should be excluded from the bid, making their bids more accurate, more competitive, and less risky.

Leigh’s overall review of Trimble Stratus as a worksite management tool? “Trimble Stratus has just blown me away. It’s awesome.”

Want to know how Trimble Stratus can help you? Learn more about how to map, measure, and manage your worksite with Trimble Stratus.

Want to know how Propeller can help you?

Learn more about Propeller’s products, pricing, and how to get started on your site.