Home/Hensel Phelps Uses Propeller to Visualize, Manage Hawaii’s Daniel K. Inouye Airport Jobsite in 3D

Hensel Phelps Uses Propeller to Visualize, Manage Hawaii’s Daniel K. Inouye Airport Jobsite in 3D

Based in Colorado, but serving every corner of the US, Hensel Phelps is a national construction and contracting company. One of their current projects is building the Daniel K. Inouye Airport in Honolulu, Hawaii, an international airport that will see a lot of air traffic.

As a company dedicated to innovation and keeping up with technological evolution, Hensel Phelps is using drone surveying and Propeller’s 3D site surveys to track, map, and measure this complex jobsite.

“We don’t want technology to be behind that VDC engineer’s computer only. We want to make sure everyone has the proper training to understand and utilize it,” said VDC Manager Angelo Lago about using new technology on Hensel Phelps’ projects. “If it’s something just to make the project look cool, we’re not interested in that.”

Hensel Phelps’ commitment to innovation means using new tools

Technology in the construction industry is always evolving, so Hensel Phelps is continually assessing new tools and seeing how they might benefit their worksites and workflows. It’s this commitment to innovation that led them to drone surveying and Propeller.

“I’ve been with the company for a long time. When I was young, CAD was pretty new and there was pushback from the industry. But as we’ve moved into VR or drones, we’ve embraced it,” noted Project Superintendent Brian Holm.

“What we’ve realized is that they are tools for conveying our plan,” he said. With a complex job like building an airport, a visual aspect like Propeller’s 3D site surveys is especially vital. “And if you understand the value of that tool and how simple it is and use to what it’s capable of—it’ll save you time and money out in the field.”

Propeller use started small and grew big

“We started using [Propeller] in smaller chunks, really identifying areas we knew were going to be working in,” said Holm.

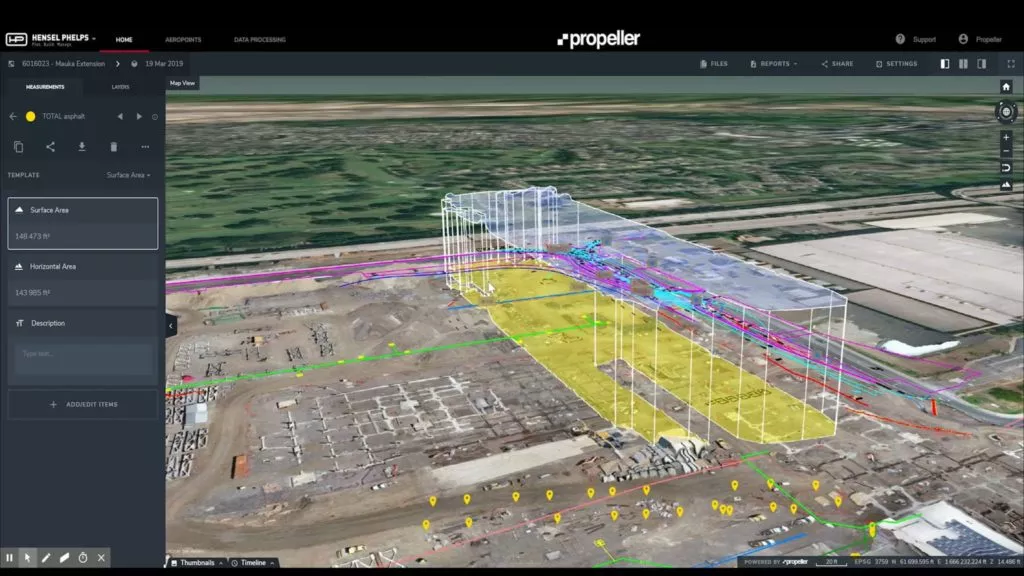

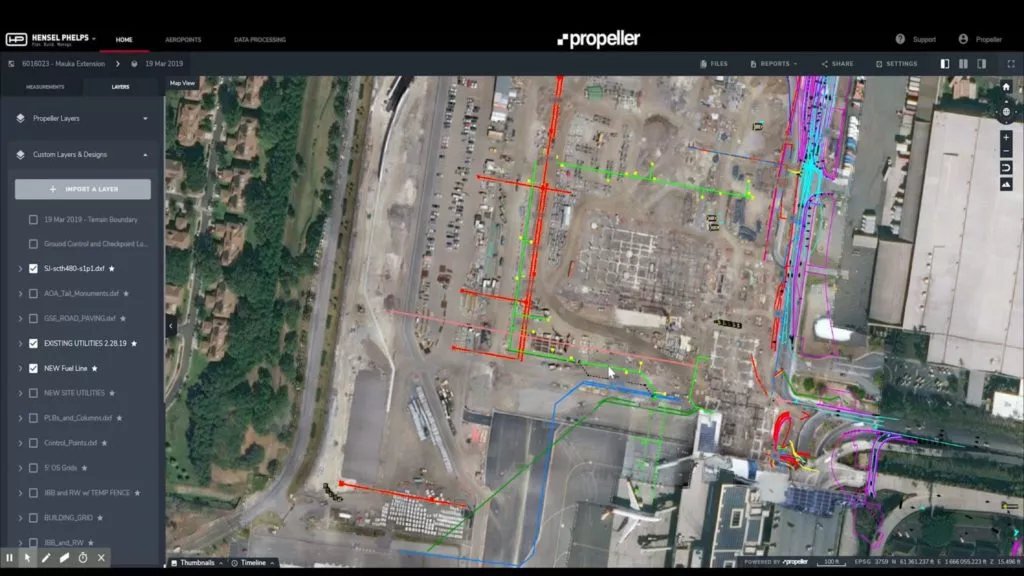

In the Platform, they’d then put layers in to view utilities on the build, both existing ones they needed to avoid and ones yet to be built. “Over time, we found more and more uses for it, really on a bigger-picture planning standpoint.” And that initial use has grown further to encompass nearly every area of the jobsite.

Current 3D site models keep people out of harm’s way

Safety is every construction site’s first priority. Hensel Phelps uses Propeller to not only take their personnel out of hazardous areas, but also do better safety briefings with up-to-date visuals of the jobsite.

“When I’m going on a job walk, it’s pretty hard to say that you’ve walked every piece,” said Adam Cotton, regional director of safety and health for Hensel Phelps. “With Propeller, it eliminates that risk. You’re seeing what your project is, you’re not having to physically go into situations [or] down in trenches. It gives you that knowledge without stepping foot on site.”

3D site visualization is invaluable for laying airport utilities

“We had three or four very large utility conflicts. We had a 16-inch water main cutting through the site that was in the wrong location [and] the main power feeds for the airport cutting through the site that were in the wrong location,” recalled Holm. These were holding up progress in different areas of the site for months.

“So we used [Propeller] to identify those impacts. We had the drone snapshot and overlays of where the existing utilities used to be and where the existing utilities ended up being.”

To capture jobsite conditions, the Hensel Phelps team flies their drone weekly. This generates lots of updated data, which gets turned into accurate 3D models.

“We can count on Propeller to help us out with the data-processing side of things,” said Lead VDC Engineer Mark Blacklin. “It takes a load off us and lets us concentrate on what we do best which is building.”

3D site maps are used in every morning meeting

At 6:30 every morning, all Daniel K. Inouye Airport’s superintendents, field engineers, and foremen meet at an office and pull up the project on Propeller.

After pulling up the imagery, they go around the room and brief each other on what they’ll be working on that day. “So we can see real-time how the site’s changed and the different areas people are going to be working on,” said Holm.

Today, Propeller is integrated into everyone’s work

“From a recordkeeping standpoint, for us, it’s invaluable,” said Holm. “Because you’ve got that snapshot of the flow of the work. You can definitely see [where] there’s work going on and where there’s no work going on. To convey that to an owner—especially if it’s trying to convey an impact or a potential impact—is invaluable.”

“If I were on a jobsite where we didn’t have Propeller, it’d be a lot less convenient and it’d take a lot more time to do things,” said Field Engineer Maggie Porter. “The bird’s-eye view gives you a really good perspective of what’s on the jobsite [ . . .] and it gives you a perspective that you wouldn’t have if you were standing on the jobsite looking at things.”

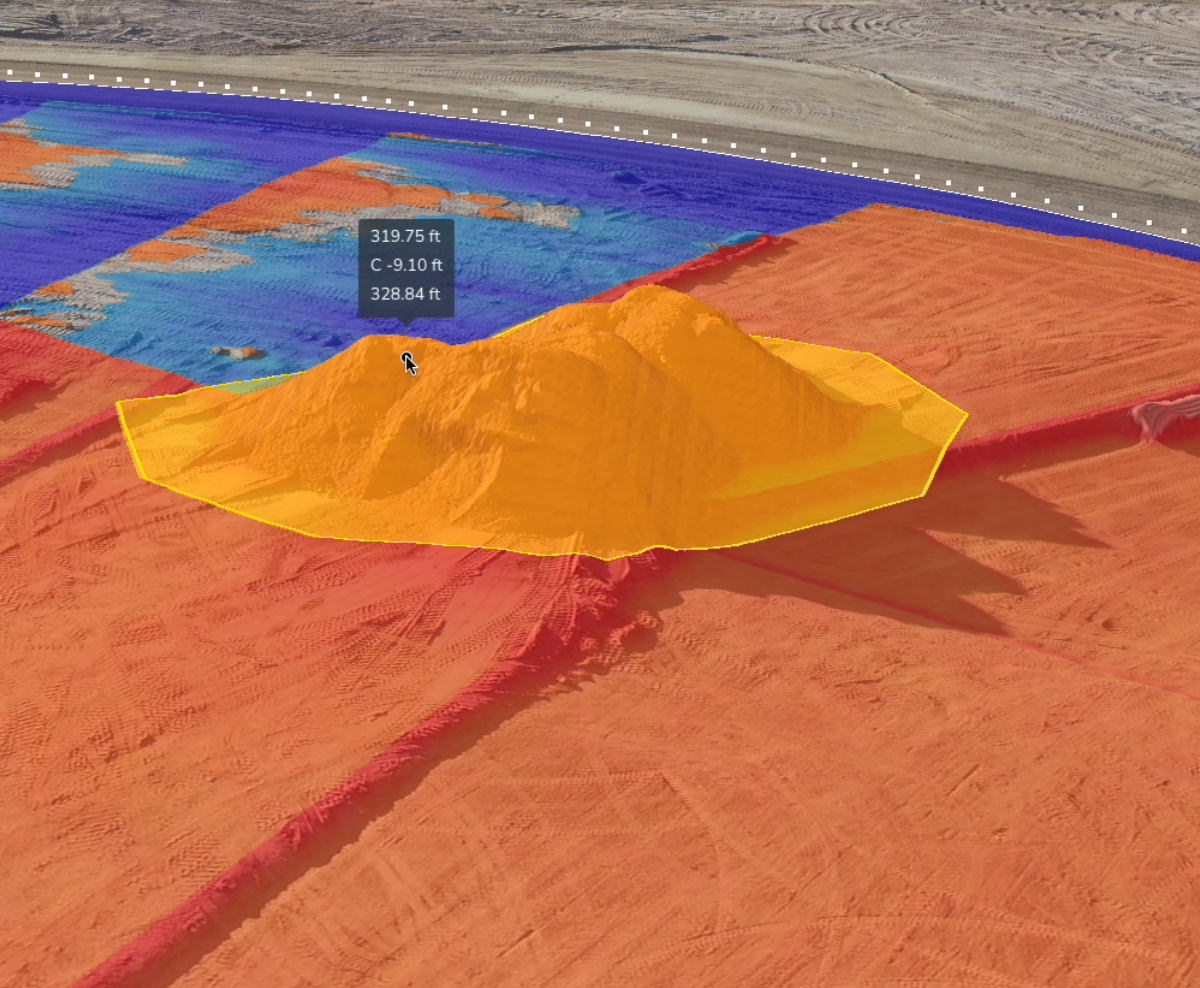

Having that view lets Porter check on stockpiles with just a few clicks. She can see if a stockpile has moved week to week or if it’s changed volume.

With small checks to big plans, Propeller empowers the Hensel Phelps team better track and manage their site—from earthmoving to design conformance.

In fact, it’s become the expected standard. But after their drones were grounded for two weeks due to the January 2019 US government shutdown (which closed nonessential functions of the FAA), Field Engineer Carter Johnson saw just how much his whole team valued the drone data.

“I’ve already had people asking when are we going to fly next, when are we going to get the updated site photo on Propeller,” said Johnson. “They’re starting to see what it’s like without an updated site image. Seeing how much it’s become part of their day-to-day process—it just goes to show how helpful the tool really is.”

Propeller has “become such a mainstream part of our process”

The Daniel K. Inouye Airport project is just one project that Hensel Phelps is using Propeller on. For the airport, in particular, integration with Propeller was fast and hassle-free.

“I don’t know if integrate is the right word to use, [. . . it] makes it sound like we had to work at it,” said Blacklin. “It’s been a natural absorption into what we do—almost effortless. Working with this data on such a regular basis and communicating quicker and easier means we’re more efficient. And more efficient means more profitable.”

Want to know how Propeller can help you?

Learn more about Propeller’s products, pricing, and how to get started on your site.