Thanks to commercial drones and drone mapping analytics platforms, surveying in the mining industry is undergoing a bit of a revolution.

Surveying is an irreplaceable part of mining, but it can be time-consuming, costly, and, depending on your operations, too infrequent. You need accurate, recent data to effectively manage ROM volumes, see progress and productivity, and conform to design.

Advances in technology have made the drone an affordable tool for mines. While they may seem like a fancy piece of equipment, drones have become no more unusual than a GPS rover, but just as vital. And unlike traditional surveyor tools you don’t need tons of special training and education to use it.

Depending on where you’re located, you might not need any certification at all—as with Australia, where flying small drones at low altitude is okay for anyone. In the US, you’d just need to get certified with the FAA.

Use drones to survey your mine

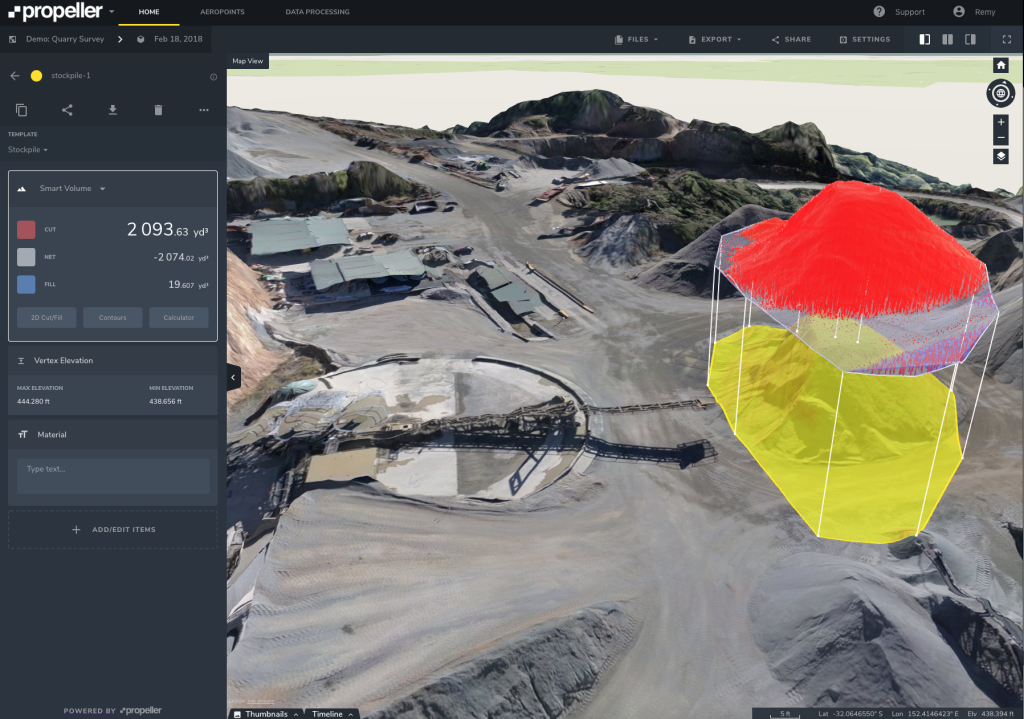

After you’ve flown your drone and photographed your mine, that’s where a processing platform like Propeller comes in.

Accessed from the browser on your device, the Propeller Platform uses photogrammetry methods and our software to stitch the images together. This involves pinning the images to the ground control positions, and getting powerful computers and data experts to digest all the raw photos, find overlaps and common points in images, and make a 3D reconstruction of the terrain.

Thanks to ground control points (GCPs), like our AeroPoints, and a known coordinate system (local calibration or otherwise), your data is accurate. This means you can measure right off the visual representation on your browser. Know your site’s progress and productivity in a few clicks by reviewing the timeline and checking the 3D site survey against design.

See what’s been extracted and what’s left to do

Using the easy-to-navigate interface takes minutes to master. We didn’t build it for scientists, we built it for regular people. You can check ROM pad volumes in seconds—and then track changes over time with our reports and timeline features.

Similarly, pit volumes are quick and simple to complete. With additional calculators, you can take the guesswork out of tonnage measurements.

While we’ll be talking more in-depth about safety later, it’s important to note that drone surveying enables you to monitor haul roads more closely and access potentially hazardous areas without endangering personnel. With frequent surveys and easy grade checks, you can keep track of performance and change roads for optimal fuel burn and measure heights of safety windrows.

Collaborate using a single source of truth

Everyone reports to somebody. Collaboration and reporting should be painless, though it’s often anything but. And collaboration challenges—internal and external—span the entire life of any mine.

At each stage, ensuring the right parties have the information to understand a project’s needs and complete their work on time, on budget, and to specification is critical to success. You and your team need to be able to check if estimates are correct, see overall progress, and ensure the right grades are going into your mill throughout the life of the mine.

Because Propeller is a browser-based tool, anyone with an internet browser can use it without installing complicated programs. Internal and external collaboration is made easy.

It’s simple to let personnel back at the main office see the same information and share measurements and notes with the whole team. Everyone can upload drone survey data from wherever they are. But this is not limited to a single mine. The Platform itself can give you an overall view of multiple mines, allowing for greater insight into each, while significantly reducing the need for site visits.

Further, it houses everything in the same place: your present and past surveys; your designs and any iterations; your notes; your reports; and, of course, all your files, in the formats you require. This makes access and collaboration, whether with the head office or your internal team, a piece of cake.

However, not every person on your mine needs, or should, know what’s happening everywhere. Propeller has no limits on the number of view-only users you can share your data with, making it simple and cost effective to give everyone the best collaboration solution available. You can set permissions for different teams or individuals, as you see fit.

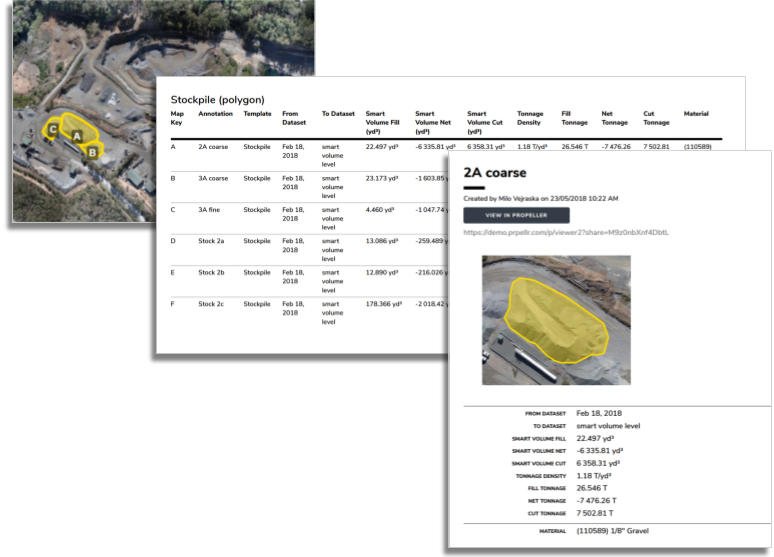

Additionally, Propeller has readable, ready-to-go reports in both CSV and PDF that you can pull to send to your boss or your direct reports. These, and the Platform overall, can help mitigate delays due to inclement weather, accidents, bad estimates, and more. With Propeller, you can close the information gap between you and your mine.

Work and plan with confidence

Measuring and managing your mine with drone data analytics saves on time and money, and prevents mistakes and rework. The Propeller Platform gives you the power to see the status of your mine in minutes, measure ROM pad volumes with a few clicks, ensure the best haul road grades for your machines, and, with rock solid data and a timeline for the life of your site, resolve disputes should they arise.

Further, you can streamline workflows related to safety and inspections, collaboration and planning, and day-to-day operations all from your browser. Cut down on commute time and cost by having a recent visual of your mine with you wherever you are.