To an outsider, earthwork can look like a magical thing—a dirt lot or empty plot of land becomes a graded landscape and the next friendly neighborhood.

But a lot of work goes into the process of taking a job site from pre-bid to design surface, and if you get the details wrong when you first start, you could end up eating a lot of unexpected costs.

That’s exactly why earthwork takeoffs are so important.

This week, we’re breaking down how to use drones to do your next earthwork takeoff, and why they’re a game-changer in the whole process.

Before we go too far down that road, though, let’s start at the beginning . . .

What is an earthwork takeoff?

An estimator can’t bid on or start a project until they know exactly how much material needs to be moved to match a design surface. There are going to be areas of cut, areas of fill, and—if there’s no way to balance the site—the need to either haul off or bring in material.

The process of measuring material quantities and estimating the costs and requirements associated with the work to be done is known as takeoff, sometimes referred to as construction takeoff, quantity takeoff, or material takeoff.

Call them what you will—it’s critical to conduct takeoffs methodically, since they are the backbone of the estimating and bidding process.

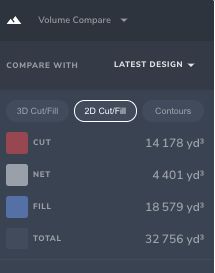

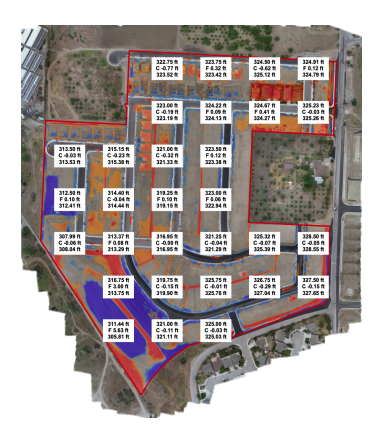

A good earthwork takeoff will leave you with a report that looks something like this: an easy-to-read summary of the difference between the design and real-world conditions as they exist today.

You wouldn’t make a major business decision with faulty or inaccurate data. If you launch a project without an accurate takeoff, you’re doing just that.

Done right, an earthwork takeoff will not only get you and your client started with a precise estimate—it will also help the entire job run more smoothly, since an accurate picture of the project means that your team will have everything they need to finish on time and without a hitch.

Takeoffs come in two main varieties:

Manual: Takeoffs done manually can be complex and laborious, and though it’s possible to generate accurate estimates from them, a small calculation error can have big ramifications. A fully manual takeoff generally involves reviewing old topographic surveys of a site, manually comparing them to a design, and calculating exactly how much material needs to be moved to make up the difference.

Digital: As you might expect, earthwork takeoff software makes the process faster, easier, and significantly less error-prone. No process is 100% error-proof, but computers make far fewer mistakes than humans do! A digital process allows for upload of digital design files, and a comparison to survey data uploaded in a digital format. With drone survey data to inform your takeoff, the digital process really shines. . . . (More on that below.)

What’s the point of a takeoff report?

The purpose of an earthwork takeoff is to inform your bid and your project launch with an accurate view of real-world conditions on a worksite today.

The critical component is existing conditions. And yet, many pre-bid takeoffs are completed using decades-old survey data.

If you won a bid with estimates from contours last surveyed in 1970, the very first thing you’ll want to do before breaking ground is to complete a fresh takeoff to compare against your bid. (If you’re lucky, you might even be able to fly the site pre-bid, which is even better!)

We might be biased, but the data supports it, too: RTK-enabled drones and photogrammetry software are just as accurate as traditional survey methods, and they’re a heck of a lot faster.

Imagine that you’re flying a site post-bid, and you find that you need to move 5,000 more cubic yards of material than you estimated in your bid. Depending on the size of the site, that could mean tens of thousands of dollars in labor you hadn’t accounted for.

You could eat the cost . . . OR, you could approach your client with evidence of the additional work, and have an early conversation about a change order.

An accurate earthwork takeoff can improve client communication, optimize labor, and protect your bottom line. If you identify even one significant discrepancy per year with your drone-enabled takeoff, you could pay for your entire program with room to spare!

How to do a construction takeoff with Propeller

Don’t let the unknowns of digitizing scare you. The whole process can be summed up in just five simple steps:

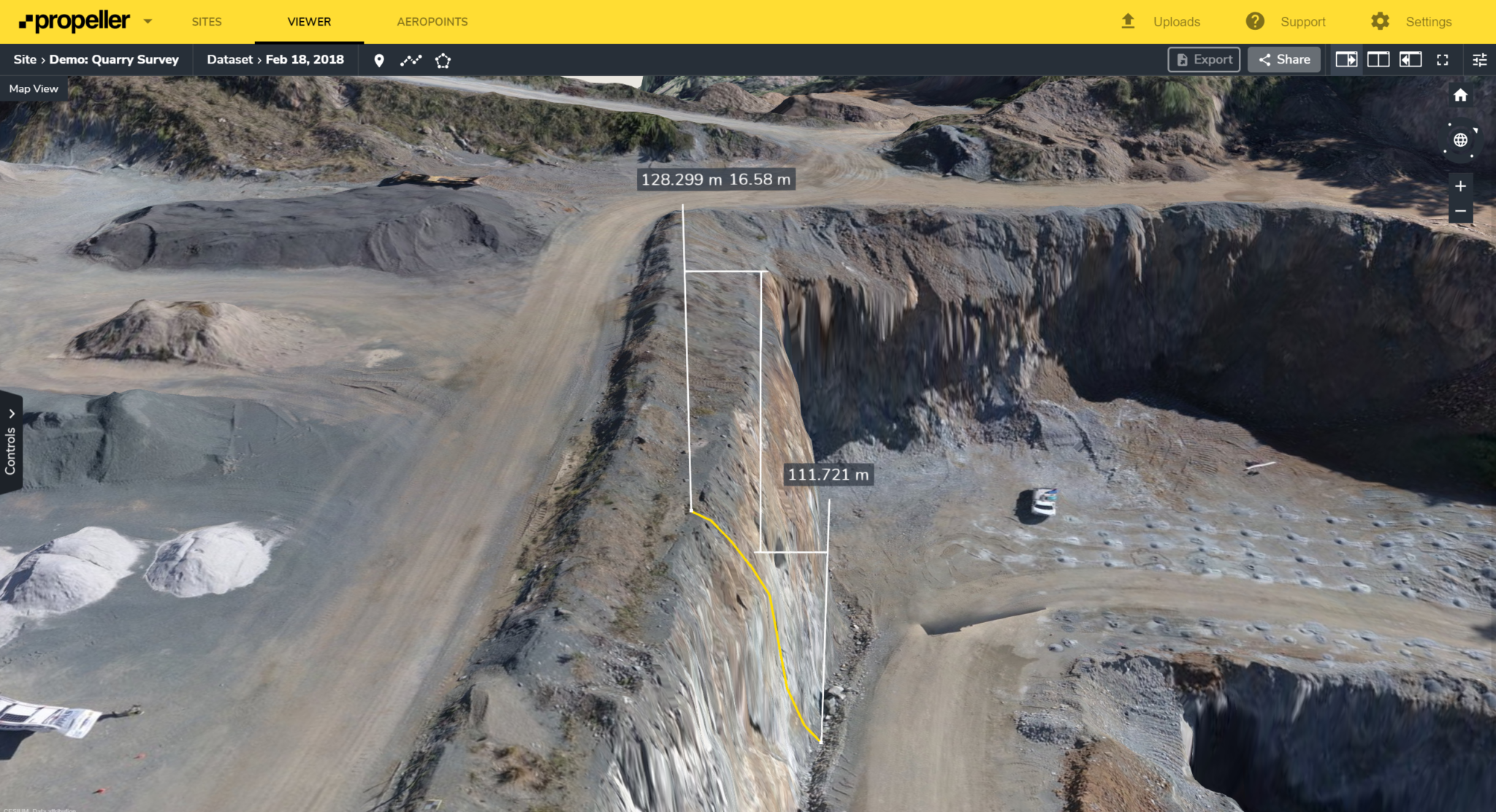

- Fly the site (pre-bid and before breaking ground): As we mentioned above, if you’re lucky, you’ll be able to fly a site pre-bid so that you’ve got the most accurate data in hand before you even submit a bid. Otherwise, your pre-bid takeoff will likely be based on existing surveys. All the more reason to fly the worksite before you break ground, so you’re gathering up-to-date contour data to inform your plan.

- Generate a 3D model: Propeller’s PPK workflow makes this incredibly easy. Just place at least one AeroPoint, fly the site, and let the platform do the rest. In just a couple of days, you’ll have an accurate 3D model of current conditions on the site. (You can also export the data to AGTEK or other earthwork takeoff software, if that’s already part of your process.)

- Upload design files: We accept DXF, TTM, KML, KMZ or CZML design files for upload into Propeller.

- Get cut/fill data against design: Generate your takeoff with the click of a button. You’ll get accurate cut and fill quantities, and see exactly how close you are to balancing the site. From there, you can put together a plan that keeps you on schedule and on budget, because you’ll know the lay of the land . . . literally.

- Share with stakeholders: Grant access to clients, contractors, or any other stakeholders who’d need to see takeoff reporting in Propeller, or generate a share link that can be sent to anyone. We’ve gone out of our way to make data-sharing easy, so you can spend your time on the important stuff! Once you can visualize and import your model, and have the report all in one place, it’s easy to share and prove out your bid.

Summary

If you’re still using a traditional topo for your earthwork takeoff reporting, you’re very likely basing your bids on old (read: bad) data, and therefore you aren’t putting your best foot forward.

RTK-enabled drones provide centimeter-level accuracy in your takeoffs and beyond, so you can submit details for a change order as early as possible and keep an eye on your bottom line.