Founded in Australia and operating approximately 700 sites in Australia, the United States, and across Asia, Boral manufactures and supplies building and construction materials multinationally. In Australia, Boral produces a range of construction materials, such as crushed rock, sand, and gravel servicing Boral’s own concrete, asphalt, and manufacturing operations, as well as its customer network.

Boral’s Victorian Metro region consists of six quarries servicing the booming market for concrete aggregates and construction materials in the greater Melbourne area.

Craig Burr is the region’s quarry support manager. Leveraging extensive experience as a production and development engineer across mineral and aggregates industries, Burr is driving excellence in efficiency, safety, and quality.

Today, Burr chats with Propeller Product Lead Chris Illuk about how Propeller’s drone-mapping and analytics solutions give the sites in his region the ability to measure and manage their stockpiles, report on inventory, and share easy-to-understand visual information for planning and tracking work.

Tell us about your inventory management and reporting process.

Once rock has been mined from the pit, it’s brought to a crushing plant where it’s turned into various grades of material. The crushing plant measures the quantities of each product coming off the crusher, and these are entered into our accounting system as stock. This stock is then stored in stockpiles around the site until it’s used to fill an order.

Based on the relevant reporting requirements, in our case twice a year, we run a report on the complete volume of all stock around the site and adjust our accounting system to match.

Historically, we relied on a third-party contractor doing six-monthly manned aircraft flights to create this report. The contractor would fly and identify all the stockpiles. This data would then be sent to site for labeling relevant material and applying densities.

What were some of the limitations of this process?

When you’re producing a million tons across the six-month duration between surveys, things can go wrong pretty quickly and errors can multiply. Previously, it would take weeks or even months, between data being collected and results being available. By this time, the inventory levels had changed, so reconciling the survey against what was on site was challenging.

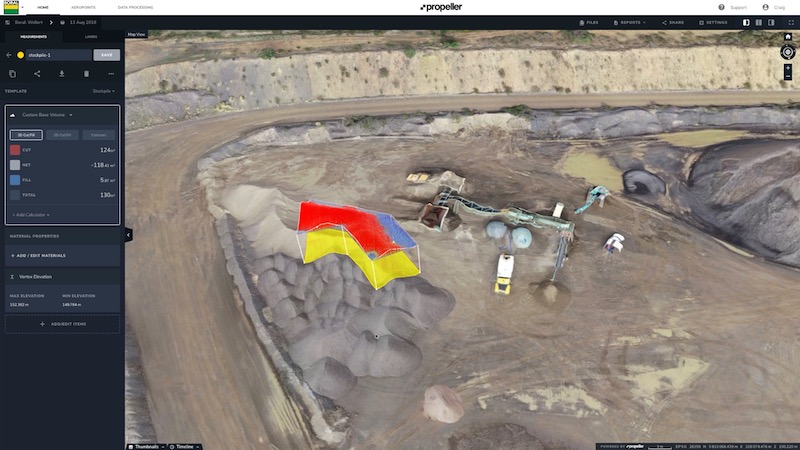

Another limitation is that our previous surveys assumed a flat base. With Propeller’s custom base tool, we’re able to adjust the base to correctly reflect the ground underneath. That’s been really helpful in reporting actual, saleable stock levels, not just estimates of what’s on the ground. For example, at our Montrose site, stockpiles are partially stacked against a hill.

Making precise adjustments to stockpile bases with the custom base tool.

What sort of results have you seen since you started using Propeller?

On our most recent survey, across all six sites we ended up with about $25,000 variance across the region, which is as good as it gets.

The site managers have also been pretty impressed with the technology. Giving these guys the tools to do it in-house minimizes the headaches on site come reconciliation time.

How has Propeller changed the process for managing your stockpiles?

Being able to do drone surveys with Propeller means we’re validating the stock on ground regularly and in real time. This allows teams on site to adjust the algorithm that dictates reported production rates. Stock on ground can then be adjusted so we have an accurate reconciliation against production rates.

We’re also able to make smaller, incremental adjustments on our stockpiles. This results in considerably less commercial impact on the business, then one big write-down come reconciliation time.

For each site, the supervisor can also now print out their own Measurement Report (as a PDF) from Propeller. This includes a picture of the stockpile, volume, tonnage, and the material. Site managers can then take that report out in the field to check that reporting volumes are physically matching up.

Outside of managing your inventory, what were some of the other challenges Propeller has helped with?

For the first time, we can independently check quantities, measure distances and road grades, estimate blast volumes, and more. We’ve gone from having almost no data to an abundance of data with minimal capital outlay.

For sites doing project work or planning, they can now quickly answer important questions themselves like, “How much land do we have left or how much do we need to clear?”, “Where can we put access?”, or “Where can we divert runoff?”

From a safety point of view, we can now check and investigate a whole variety of issues without having to send people into the quarry pit.

How does Propeller compare to other tools used in the industry?

Other products I’ve used in the past usually work with a DTM surface model. You don’t have the visual platform, which lets you measure what you’ve got while being able to clearly see “that’s clearly part, or that’s not part, of the volume of the material.”

The Platform is also simple to use. The fact that Propeller is so visual makes it easy, even for those who are not as technically savvy. They’re able to move points around on a picture and get detailed data. For those guys, it gives them the ability to manage their own stocks for the first time.

Pricing strategies for some of the big desktop software packages puts limits on how many users we can have in the system. With Propeller, we can add anyone who needs access.

How have you managed the process of getting new people up to speed with Propeller across your sites?

No one has any formal training and they’ve intuitively figured out what’s important for them. Often I’ll have a video conference with a team member, and within half an hour they’re up to speed and able to get the information they need.

Our metropolitan team is also now able to do a monthly video conference where we share a screen. Each site can update me on their various challenges, whether they’re production or planning related, with an accurate, up-to-date picture in front of us. This has reduced the need to physically travel to each site.

Why would you recommend Propeller?

The three things for me are the ease-of-use, the cost, and the speed.

The three things for me are the ease-of-use, the cost, and the speed.

The ease-of-use is just how easy it is to get anyone to go out and collect the data, upload it, and start getting the information they need.

On the cost side, we were previously paying thousands per survey. Propeller flights work out to a fraction of that—and we get better data quicker.

That sets up the last point. Speed. It’s the turnaround. Our data gets turned around within 24 hours. Previously we were waiting two or three months to get aerial survey results.

I also find myself recommending Propeller based on tech support. Over the last year, in the times I’ve needed it, support has been exceptional. If I’ve got a problem, I just message tech support and it always gets resolved.