Advances in technology have made the drone an affordable tool for worksites. While they may seem like fancy pieces of equipment, drones have become no more unusual than a GPS rover, but just as vital in recent years.

Unlike traditional surveying equipment, however, you don’t need tons of special training and education to use it.

Used correctly, drones enable faster, more economical, and higher-resolution surveying, without sacrificing on accuracy. A successful drone program on your landfill can provide your business with accurate, up-to-date information on your site’s progress and productivity, and information you can use to ensure high-quality work and minimize operational risks and costs.

Collecting and processing your data is only half the story.

Web-based platforms can translate your raw data into something readable and actionable. Take our own Propeller Platform: it takes your data and transforms it into a 3D survey of your site. Fully navigable. Fully measurable. It’s run in your browser, so you can forget about the clunky and complex desktop software of the past.

(Don’t have time to read the full guide right now? Save it for later, plus gain access to additional content.)

Key components of a successful drone program on your landfill site

You’ll need the right hardware, the right software, and the right licenses (if applicable). We’ll go through these one by one further down.

For a successful drone program, remember to keep it simple, scalable, and economically efficient. Basically, choose your program with overall ROI at top of mind.

Check your local aviation regulations

Usually, all unmanned aerial vehicles (UAVs) are overseen by the country’s aviation regulator, so check out your country’s website if you’re not finding information elsewhere.

Choose the optimal hardware for your worksite

When it comes to using drones in waste management there are many to choose from, but to pick the one that’s right for your needs you should consider a few factors. How big is your survey area? What’s your budget? What’s the best camera for your surveying purposes?

Drone type

If your area is less than 200 hectares (500 acres), it can be done comfortably with a multicopter. If it’s larger, you may want to consider either more than one multicopter or a fixed-wing UAV.

(But remember, if you are operating in a restricted area or a busy place near moving equipment, you may not be able to use fixed-wing aircraft due to their weight and the need for a vacant “runway” strip of land.)

Budget

Cost, of course, plays a big factor in your drone choice. Typically, multicopters (especially those made by DJI) are mass produced and can be purchased easily and cheaply.

Fixed-wing UAVs are still made in limited quantities, meaning units are significantly more expensive—sometimes up to a hundred times more pricey.

Availability and ease of maintenance

Along with sticker price, keep in mind the added cost of maintenance and the availability of parts and replacements.

It’s best to stick with simple options that are available at local stores. As with any other worksite tool, it’s best to avoid providers who cannot guarantee quick repairs or replacements. You don’t want to postpone your surveys because you’re waiting on a replacement drone or part.

A great example of the value of availability in action comes from what would usually be a dreaded event: crashing your drone. Recently, one of our partners was flying a site and crashed his drone, due to a combination of high winds and probably mechanical failure. But because he was flying a DJI drone, a widely stocked craft, he was able to purchase a replacement at a local store and start flying again two hours later.

A RTK/PPK-enabled craft

With the release of an affordable RTK craft in DJI’s Phantom 4 RTK, getting uniform survey-grade accuracy across your site is not only possible, but the new standard.

Real-time kinematic (RTK) processing on a drone records GPS information and geotags images as they’re captured. An active base station on the ground sends raw GPS data to the drone, which it combines with its own data to accurately determine position. During flight, the RTK drone must stay connected to the base station while gathering data. Signal loss can occasionally occur. If this happens, data can be lost while trying to get a signal lock again. You’ve probably heard of another kind of drone surveying—PPK. The difference between PPK and RTK is where things get tricky because we’re not strictly comparing apples to apples. PPK isn’t hardware; it’s a different processing workflow using an RTK drone. PPK stands for “post-processing kinematic.” With PPK, the drone will geotag X,Y,Z coordinates to each image based on its GPS unit.

While this is happening, a base is also recording the positional information on the ground, but with much more accurate triangulation. After the flight, those two sets of GPS data are matched up using the photo timestamp and the drone’s initial GPS data is corrected, giving precise geotags for the imagery. Those images are then used to build your site survey.

Propeller’s own solution, Propeller PPK, allows you to achieve 1/10ft accuracy site-wide with only one AeroPoint and DJI’s Phantom 4 RTK in a PPK workflow.

Cameras

A good camera for surveying purposes should have a 20MP (or better) sensor. Avoid cameras with interchangeable lenses unless you are certain you’ll need that feature (often used for inspections). They over complicate the surveying process and often worsen the quality of data with images that can be out of focus.

Overall, keep in mind the camera specifications that affect ground sample distance (GSD) and resolution.

The GSD is the real-world size of a pixel in your images. This generally sets a physical limit on the accuracy of your aerial survey. For example, if your GSD is 5cm, the survey produced will only be accurate down to 5cm.

GSD is measured in cm/pixel, usually ranging from less than 1cm up to 5cm for aerial surveys. Note that the altitude of your flight also affects this number. If you want to fiddle with possible GSDs, this handy calculator can compute them for you.

In general, make sure you have a high-resolution camera, with a larger sensor and a 35mm-equivalent focal length. This lets you get more detail about any point and increases your image contrast in order to help generate better 3D renderings and point clouds.

If you want to go deeper on this topic, check out our article on what makes a good camera for drone surveys and inspections.

Pick the right software for your needs

As we’ve seen, there are various options for the hardware side of things, but you can usually rig together some combination to acquire the data you need. Software, however, is a different matter. It’s not an interchangeable tool. Landfills are complex, involving many levels of oversight, design, and management. You need to pick the software that’s right for your workflows.

Interested in finding out which flight planning app we recommend to customers and understanding what you really need to know when it comes to selecting the right processing, measurement, and visualization software. Download the full guide below.

Use your landfill survey data to spend less and make more

Drones cut down surveying times to hours instead of days, and they’re cheaper than traditional survey equipment. There’s a whole lot more that drones can do for waste management, however. Let’s look at workflows to see how you can use your data to best effect.

Calculate remaining airspace

Better landfill performance means getting the most waste under the top-of-waste (TOW) design as you can. Because of compaction rates, you overfill cells selectively and depend on waste settling back down under the cap.

But overfilling too much can spell catastrophe—that is significant repercussions from your environmental protection agency or local council. Sometimes this means sinking time and money into digging the waste back down to spec. With drone-captured surveys, you can measure overfill and remaining airspace easily. Sometimes in just a few clicks. This is a big change from traditional methods. In the past, you’d need to walk multiple lines across the landfill, use those points to interpolate an approximate elevation model, and then compare that model against the TOW design. But with 3D surveys, rendered by processing platforms like Propeller, allow you to measure volumes right on the visual model. Because the drones capture data in all three dimensions, you can see cross sections of your cell or site over time and, most importantly, against design.

But overfilling too much can spell catastrophe—that is significant repercussions from your environmental protection agency or local council. Sometimes this means sinking time and money into digging the waste back down to spec. With drone-captured surveys, you can measure overfill and remaining airspace easily. Sometimes in just a few clicks. This is a big change from traditional methods. In the past, you’d need to walk multiple lines across the landfill, use those points to interpolate an approximate elevation model, and then compare that model against the TOW design. But with 3D surveys, rendered by processing platforms like Propeller, allow you to measure volumes right on the visual model. Because the drones capture data in all three dimensions, you can see cross sections of your cell or site over time and, most importantly, against design.

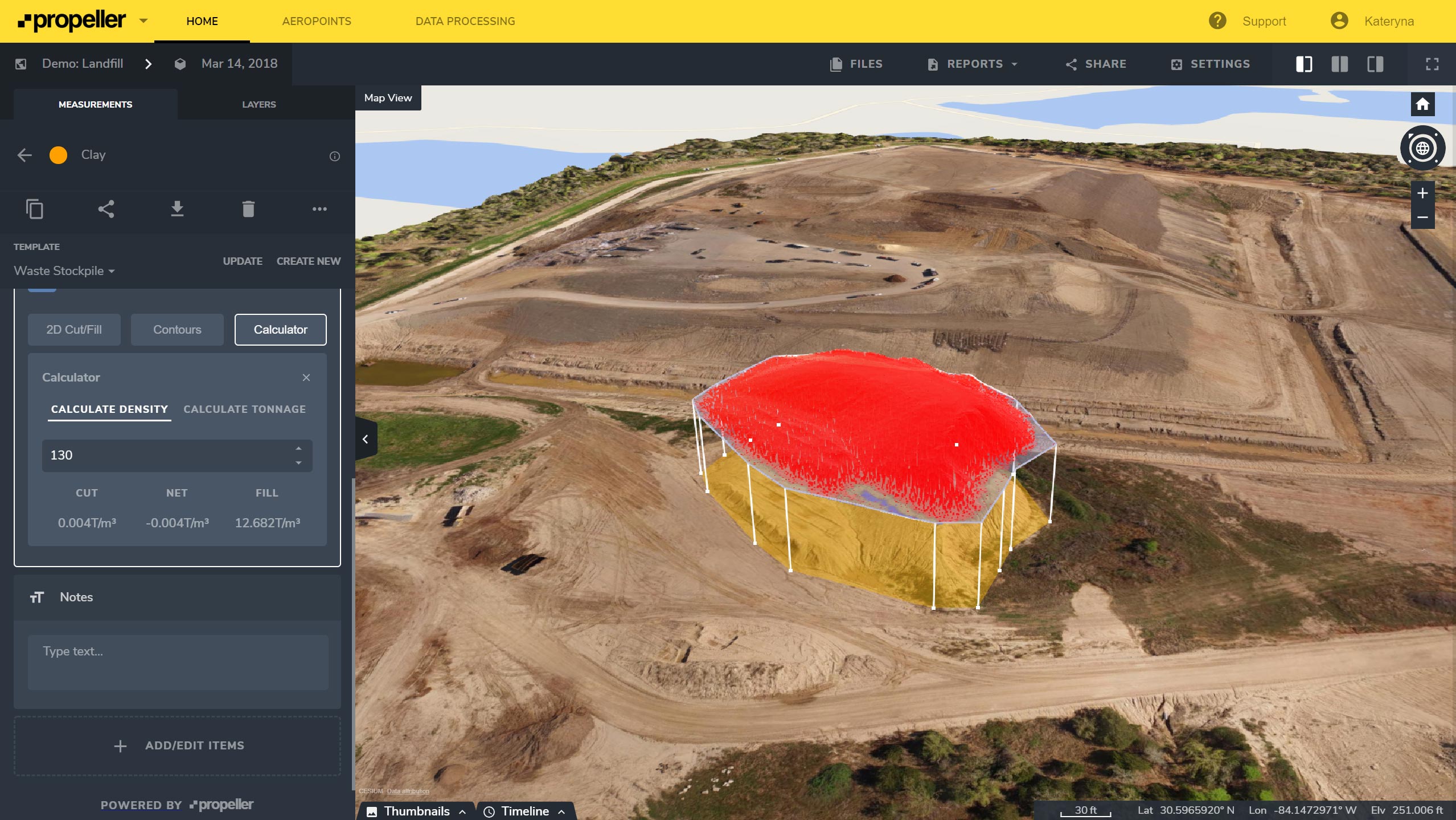

Improve landfill cell management

Since landfills are paid per ton of waste and you’ve only got a set amount of airspace you can fill, you want to be able to put in as much waste as possible to get the best performance from your site. You want the best possible compaction rate. As you might guess at this point, drones can help with that too. Basically, it works like this: weighbridge + drone + processing platform = measuring compaction every time you fly. Now that probably sounds too easy, but that’s the gist. Once you survey your site, you can compare volumes on individual cells from survey to survey. Couple that with your weighbridge data and a density calculator like Propeller’s, you can get your rate in a snap.  Now this data can also be exported into CSV and PDF files for the necessary reporting, or you can share those measurements with colleagues and bosses directly from your platform.

Now this data can also be exported into CSV and PDF files for the necessary reporting, or you can share those measurements with colleagues and bosses directly from your platform.

Manage environmental areas

Monitoring environmental areas is vital for any landfill. With drone surveys, you have the visual data on hand to easily indicate both of those things. Since everyone is working from the same data, you have one source of truth that everyone can rely on. And with cloud-based processing platforms, you can share the data with your team.  If you have an area that requires regular reporting, just mark it out once and share it with everyone who needs to know. From there, every time you survey your landfill, you can include visual updates on that area in your reports.

If you have an area that requires regular reporting, just mark it out once and share it with everyone who needs to know. From there, every time you survey your landfill, you can include visual updates on that area in your reports.

Drones are revolutionizing the waste management industry

Waste management is a multifaceted industry with many moving parts, accountability, progress tracking, and accurate data are key to success. But, as we’ve seen here, too often you don’t have the tools you need to accomplish your job on time and on budget, not to mention make day-to-day management easier. Drones can drastically improve these issues by solving problems quicker, with less trouble, and through less costly means.  Using a drone on your site does not require someone with extensive special training, often you can learn how to fly it yourself and obtain the required certification without hassle. A processing platform like Propeller is cloud-and browser-based, which means that you can access you survey data on your device from wherever you are. Now all of this is great to think about theoretically, but when it comes down to it, what are companies actually seeing when they start using drones and processing software?

Using a drone on your site does not require someone with extensive special training, often you can learn how to fly it yourself and obtain the required certification without hassle. A processing platform like Propeller is cloud-and browser-based, which means that you can access you survey data on your device from wherever you are. Now all of this is great to think about theoretically, but when it comes down to it, what are companies actually seeing when they start using drones and processing software?

Here are a few examples of real people solving real problems on their sites:

“I can go out and fly a site in two to three hours and then just upload everything to Propeller and come in the next day, and it’s done. If I have a question or something, I can just email someone and usually within a few hours—or within 24 hours—I have a solution back. It simplified everything that we do. Before, we weren’t doing a lot of monitoring on every site, so now we try to fly every site at least once a month.” —Jim Croan, JRC Construction “Propeller is an intuitive product, which has improved our communication and decision making.” —Richard Lockwood, Cleanaway