Justin Russell, the head surveyor at from Fiore & Sons, Inc., was overrun with requests for site status updates.

“Where jobs are at, quantity-wise. That’s probably the most important question I get asked every day,” says Justin. “PMs, foremen, even supervisors, they want to know where their jobs are at…what needs to be done and what has been done, so they can track their costs.”

It’s an obstacle most construction surveyors have experienced: Every decision maker in your company wants answers faster than you can get them yourself. To help accelerate the flow of progress updates, Justin started researching drone surveying. It wasn’t long until he found Propeller.

“I was talking to other people who had started doing drone stuff,” says Justin. “They were doing in-house processing, and it takes days sometimes for their computer to process a topo. With you guys, it’s quick and simple. You just upload everything, get your data back usually in 12 to 24 hours, and you aren’t spending too much screen time trying to process. You just upload and go.”

Recently, Justin sat down with Michael Scott, one of Propeller’s regional sales managers, to discuss all the advantages he’s seen since adopting Propeller’s workflow—including faster topos (that don’t skimp on the accuracy), better information-sharing, and safer working conditions.

You can check out their conversation in the video below, or read on for a summary of what they discussed.

(Note: Fiore & Sons, Inc. is a Trimble customer. Trimble, the global leader in positioning technologies, was an early partner of Propeller. Our teams work closely together to deliver Trimble Stratus survey-grade drone data solutions for the heavy civil industries.)

Propeller enables Justin to topo his sites in a fraction of the time—without sacrificing accuracy

A year and a half ago, before incorporating Propeller into his workflow, Justin was topo-ing “one, maybe two” sites a day. Now?

“Six topos a day is my record,” says Justin. And with Fiore’s Colorado-based sites averaging 100 acres, that’s no small feat. Before Propeller, Justin says his job almost solely consisted of “an awful lot of field work.” Now he’s able to survey the same sites in fraction of the time, without compromising the quality of his work.

“Accuracy is everything,” says Justin. “We’re comparing an existing surface to a design, and if that existing surface isn’t accurate, you’re just fooling yourself.”

Accuracy is the cornerstone of Propeller’s appeal. We know that without being able to deliver similarly accurate measurements that surveyors can get through more traditional means, we’d be a much less valuable investment.

The best way to achieve these results is through Propeller’s PPK workflow, which combines smart ground control, in-flight geotagging, and post-processing to deliver highly accurate measurements. Justin leverages our PPK workflow, and has seen outstanding results.

“Most of the time, it’s way more accurate than a tenth of a foot from survey to survey. I have a sidewalk on the exterior of one site that obviously doesn’t move. I just run a quick calc of an area on that sidewalk and most of the time it’s the same to two to three hundredths of a foot every time.”

From convincing management to letting them track quantities in the platform themselves

Drones are still a relatively new technology in the surveying world, which means there’s often some convincing required to prove their value. With Fiore, it was no different.

“Upper management is old school, so getting new technology through with them is always a difficult thing,” says Justin. “They wanted to see proof in the pudding. It took me a couple months to get them sold on it. They were questioning it every time I flew. “Even though I would also do a ground topo for either the entire site or a chunk of the site, they were still questioning the data.”

After a few months of seeing what Propeller was capable of, management’s skepticism started to vanish.

“They’re not asking me if my drone data is good anymore,” says Justin. “They’re becoming way more reliant on it. It’s turning out to be quite a good thing, because I’m giving access to the site they can go in and see it for themselves.”

Allowing management to check quantities themselves in the platform hasn’t just helped with convincing them of drone mapping’s value—it’s also lessened the burden on Justin, who previously served as more of a gatekeeper for mission-critical data.

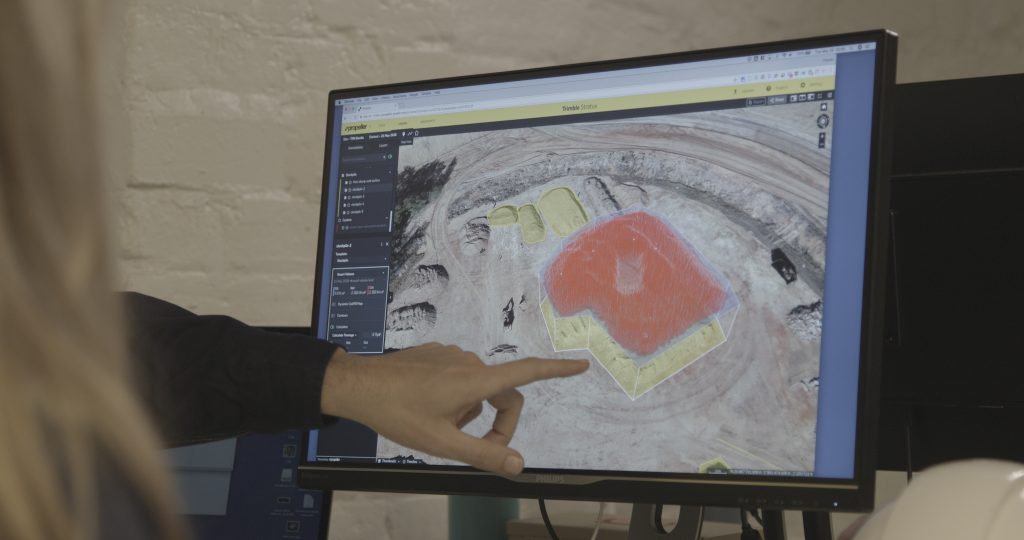

“Our PMs and foremen log in to the platform and can see the topos I produce. The pictures are a lifesaver. They can tell what’s going on now. They can do quick calcs in there for quantities they want to know. If they want to know what’s in this stockpile, they can check it themselves. They don’t need to call me and bug me with small things like that.”

Fringe benefits: less rework and increased safety

When asked about any “big wins” that have stood out to him since Fiore adopted Propeller, Justin mentions one case in which having months worth of aerial photos of a site helped them fend off a faulty claim about their dirt..

“We were sorting through all this dirt, pulling out concrete, and hauling it to recycle, and a couple months later they came back and said there was all this kind of iron and rebar in the concrete and wanted to charge an extra fee for taking it to them.

“I had flown everything and gotten the quantities, so we had all photos to back it up. We showed them the photos, asked them where all the iron was at, and they ended up having to ixnay the bill. Tens of thousands of dollars we saved ourselves there.”

Another big advantage of drone surveying is that it doesn’t require a surveyor to walk an entire site in order to topo it. Drone flights can be executed from a safe location, away from the hazardous high-traffic areas of a worksite.

“Before Propeller, I was in there with the scrapers. Getting the data I need today, I can stay away from them. I just run around, set up my AeroPoints, and take off from a safe distance. It’s a lot nicer having to not be around them any more.”