Making decisions with the most up-to-date and reliable information is critical for any site manager, especially when planning and executing blasting work on a mining site. Keeping your site survey and bench level plans updated and accurate can dramatically improve blast results and significantly reduce drilling and blasting costs.

To give you more confidence in your blast planning, any area of interest can be easily and inexpensively surveyed with drones and the Propeller Platform. Once the drone-captured photos are uploaded to Propeller you can generate accurate 3D models and georeferenced orthophotos of the blast area for further measurement and analysis. Centimeter-level accuracy of the final model is achieved by placing the ground control points such as Propeller AeroPoints across the surveyed site.

Drone surveys often takes less than an hour to complete, even on larger sites with the data processed and available on Propeller Platform within 24 hours for detailed evaluation.

The information useful for blast planning can be obtained from 3D models and orthos include rock type variation in a bench, face angle, preblast block condition, and blast volumes.

Measuring rock face angle is essential for correct blasting.

Detailed georeferenced models can be also used to overlay drilling and charging designs and define whether the drill pattern should be adapted according to the existing geometric and geologic conditions. This information is particularly useful to pit managers, planning engineers, geologists, and blasting consultants.

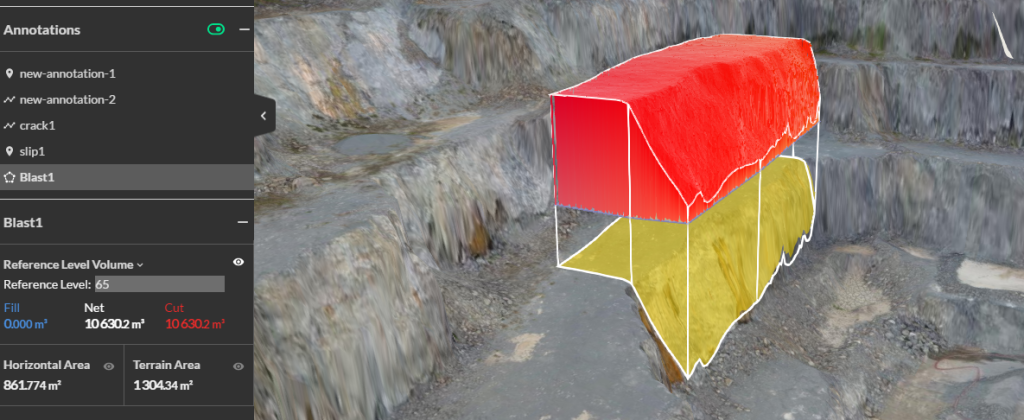

When planning blast works to fill a specific customer’s order, a volume to blast can be easily identified on the 3D model using Propeller volume to reference measurement tool. Draw a polygon around the proposed blast area, set the bench level to blast to and get automatic volume calculations.

Blast volume to reference measurement using the Propeller Platform

High-resolution drone photographs provide timely and detailed data for rock face evaluation which impacts both on blastability and explosives performance. Once the blasting work is complete, it will take another hour or less to capture drone data for the detailed postblast analysis.

These still images also provide good source of data for visual assessments of blast results such as muckpile shape, back damage, distribution and fragmentation. You can better plan postblast logistics using the fragments size and location data. Measure pile volume, fragments size, add annotations, and share blast reports with the stakeholders directly from the Propeller Platform.

With the Propeller volume compare tool, the blasted volume can be compared against the plan to ensure the right amount of material was extracted.